- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

JunHe

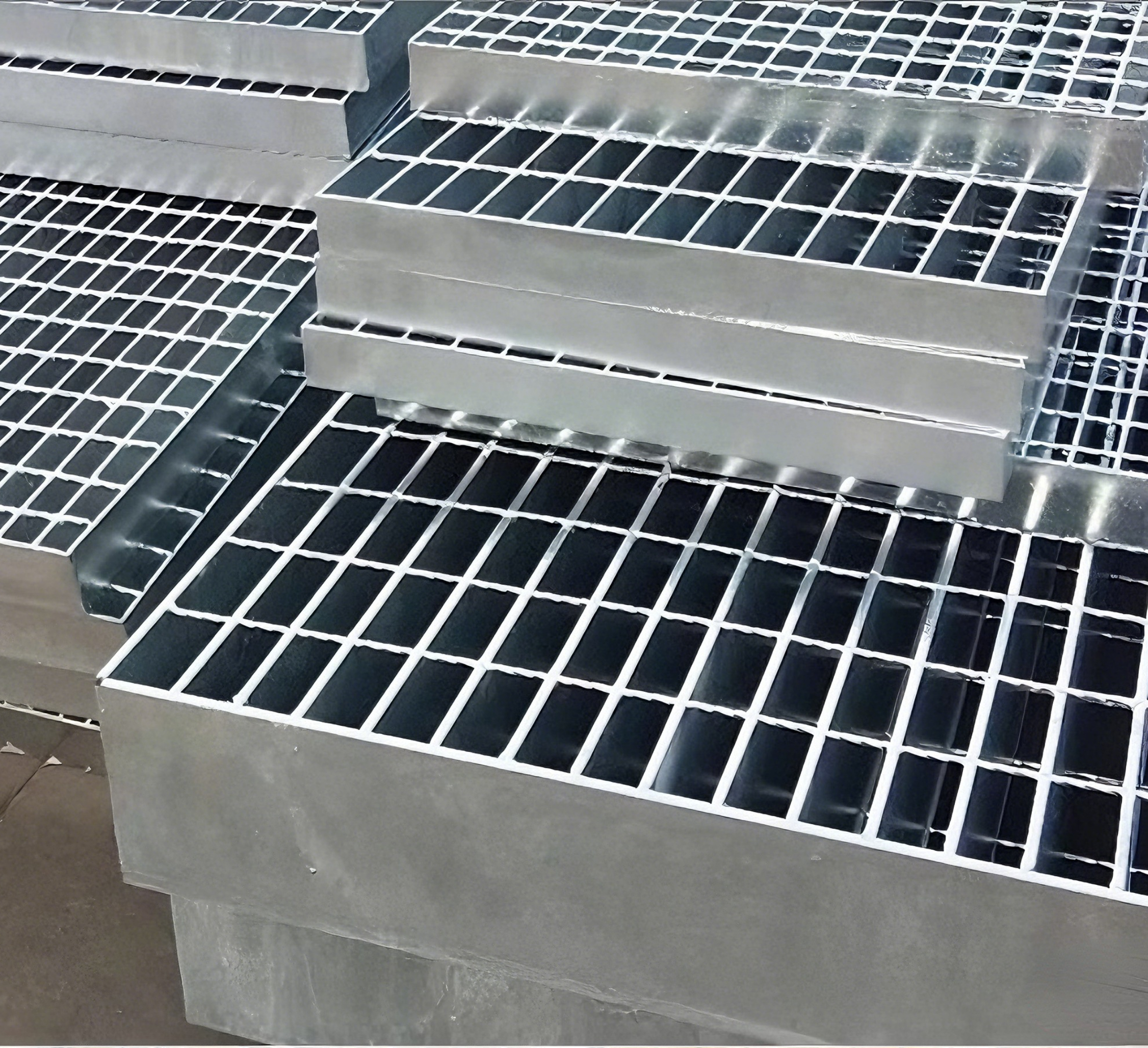

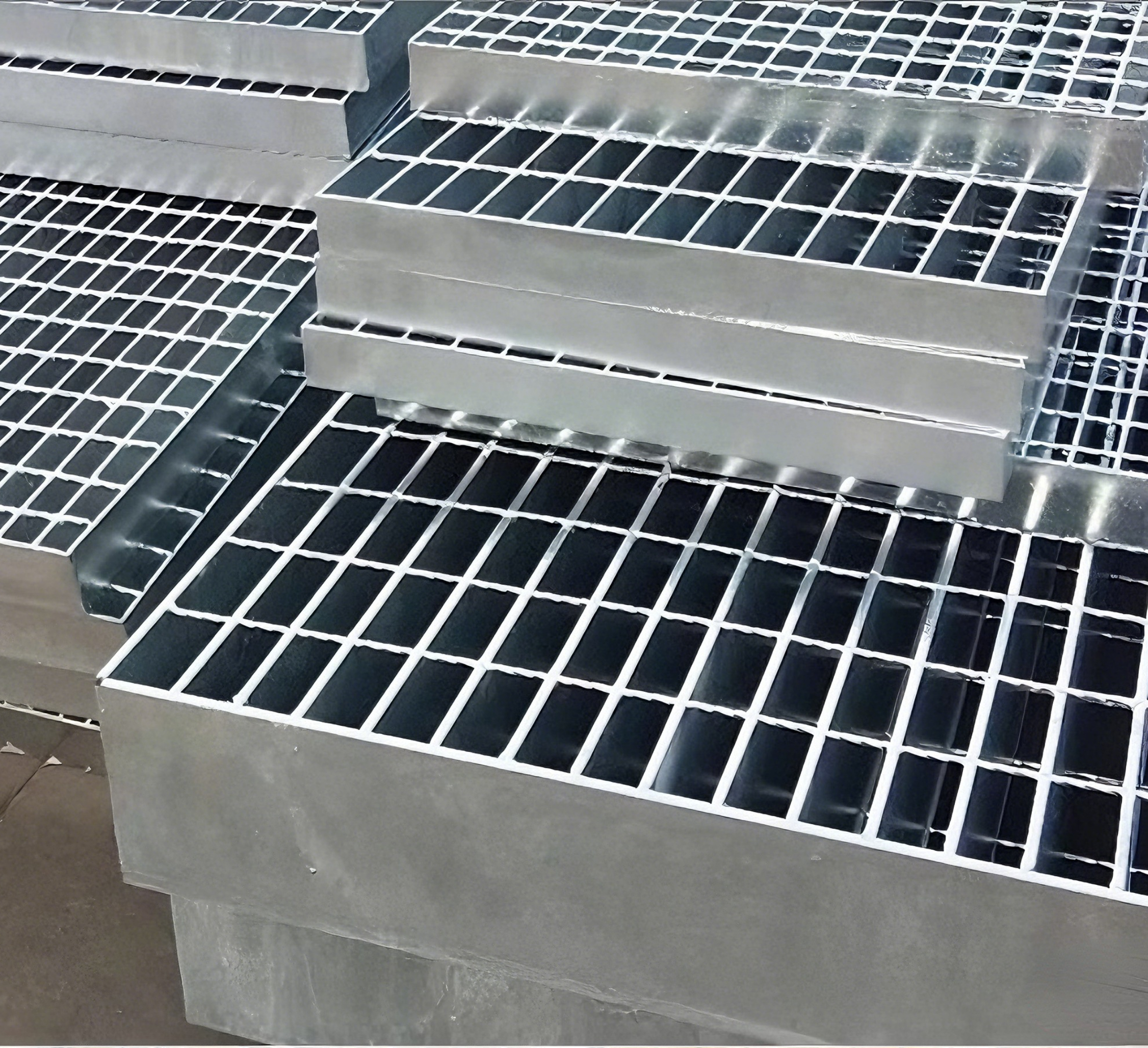

Hot - Dipped Galvanized Steel Grating: Core Benefits

Through hot - dipping, a thick zinc layer forms on its surface, blocking rust and corrosion. It lasts over 20 years outdoors, great for chemical plants and coastal areas.

Crafted from quality steel bars with a smart bar combo, a standard type can bear 3 - 5 tons/m². Suitable for heavy - duty industrial and traffic areas.

Unique surface patterns increase friction. Anti - slip coefficient > 0.6, preventing slips on wet or dusty walkways and stair treads.

Pre - made for quick installation with bolts or welding, saving time and labor. Minimal maintenance, just occasional checks to cut long - term costs.

Common specifications of load - bearing flat bars include 20×5, 25×5, 30×3, 30×5, 40×5, 50×5, etc. (unit: mm), and common specifications of cross bars are 5×5, 6×6, 8×8, etc. (unit: mm). Different specification combinations can meet different load - bearing requirements.

Commonly used ones are 30×100, 40×100, 60×100 (unit: mm), etc. Smaller mesh sizes are suitable for occasions with high safety protection requirements to prevent small objects from falling. Larger mesh sizes focus more on functions such as ventilation and drainage and have relatively lower costs.

After hot - dipping galvanization, the average thickness of the galvanized layer is not less than 85μm, and the local thickness is not less than 70μm. The thickness of the galvanized layer meets national standards, which can effectively ensure the corrosion resistance of the product and extend its service life.

The bearing capacity varies according to different specifications. For example, for the 303/30/100 - specification steel grating, the uniform load can reach 3.5kN/m², and the concentrated load can reach 3.85kN. The appropriate specification can be selected according to the load requirements of the actual use scenario.

The hot - dipping galvanization process is mainly used to form a uniform and dense zinc layer on the surface of the steel grating, greatly enhancing its corrosion resistance. In addition, other surface treatments such as cold galvanization and painting can also be carried out according to customer needs.

Before installation, check the size and quality of the hot - dipped galvanized steel grating. For installation, align the grating accurately and secure it firmly with bolts or welding. When using in high - load areas, ensure the load does not exceed its capacity. Regularly inspect for any signs of damage or corrosion. This simple process ensures long - term, safe use of the steel grating.

Q: How long can the hot - dipped galvanized steel grating last?

A: In normal outdoor conditions, it can last over 20 years due to the thick anti - corrosion zinc layer. But lifespan may vary in special environments like chemical plants.

Q: Can the steel grating be customized?

A: Absolutely. We can customize the size, shape, and load - bearing capacity according to your needs. Just let us know your specific requirements.

Q: What's the installation process like?

A: It's quite simple. First, align the grating accurately. Then, secure it using bolts or welding. Installation time is short, saving you both time and labor costs.

Q: How to maintain the hot - dipped galvanized steel grating?

A: Maintenance is easy. Just conduct occasional inspections. Since it has high corrosion resistance, there's no need for frequent upkeep. Only repair if any damage is found.

Hot - Dipped Galvanized Steel Grating: Core Benefits

Through hot - dipping, a thick zinc layer forms on its surface, blocking rust and corrosion. It lasts over 20 years outdoors, great for chemical plants and coastal areas.

Crafted from quality steel bars with a smart bar combo, a standard type can bear 3 - 5 tons/m². Suitable for heavy - duty industrial and traffic areas.

Unique surface patterns increase friction. Anti - slip coefficient > 0.6, preventing slips on wet or dusty walkways and stair treads.

Pre - made for quick installation with bolts or welding, saving time and labor. Minimal maintenance, just occasional checks to cut long - term costs.

Common specifications of load - bearing flat bars include 20×5, 25×5, 30×3, 30×5, 40×5, 50×5, etc. (unit: mm), and common specifications of cross bars are 5×5, 6×6, 8×8, etc. (unit: mm). Different specification combinations can meet different load - bearing requirements.

Commonly used ones are 30×100, 40×100, 60×100 (unit: mm), etc. Smaller mesh sizes are suitable for occasions with high safety protection requirements to prevent small objects from falling. Larger mesh sizes focus more on functions such as ventilation and drainage and have relatively lower costs.

After hot - dipping galvanization, the average thickness of the galvanized layer is not less than 85μm, and the local thickness is not less than 70μm. The thickness of the galvanized layer meets national standards, which can effectively ensure the corrosion resistance of the product and extend its service life.

The bearing capacity varies according to different specifications. For example, for the 303/30/100 - specification steel grating, the uniform load can reach 3.5kN/m², and the concentrated load can reach 3.85kN. The appropriate specification can be selected according to the load requirements of the actual use scenario.

The hot - dipping galvanization process is mainly used to form a uniform and dense zinc layer on the surface of the steel grating, greatly enhancing its corrosion resistance. In addition, other surface treatments such as cold galvanization and painting can also be carried out according to customer needs.

Before installation, check the size and quality of the hot - dipped galvanized steel grating. For installation, align the grating accurately and secure it firmly with bolts or welding. When using in high - load areas, ensure the load does not exceed its capacity. Regularly inspect for any signs of damage or corrosion. This simple process ensures long - term, safe use of the steel grating.

Q: How long can the hot - dipped galvanized steel grating last?

A: In normal outdoor conditions, it can last over 20 years due to the thick anti - corrosion zinc layer. But lifespan may vary in special environments like chemical plants.

Q: Can the steel grating be customized?

A: Absolutely. We can customize the size, shape, and load - bearing capacity according to your needs. Just let us know your specific requirements.

Q: What's the installation process like?

A: It's quite simple. First, align the grating accurately. Then, secure it using bolts or welding. Installation time is short, saving you both time and labor costs.

Q: How to maintain the hot - dipped galvanized steel grating?

A: Maintenance is easy. Just conduct occasional inspections. Since it has high corrosion resistance, there's no need for frequent upkeep. Only repair if any damage is found.