- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

JunHe

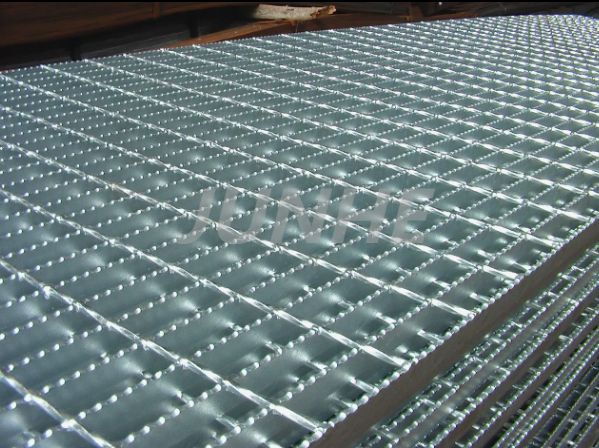

Hot-dip galvanized steel grating is widely used, typically seen in flooring, stair treads, and fencing. It is crafted from Q235 low-carbon steel or stainless steel.

The frequently used dimensions for load-bearing flat steel are 20×5mm, 25×5mm, and 30×3mm.

Horizontal bars commonly come in sizes of 5×5mm, 6×6mm, and 8×8mm.

The standard mesh sizes include 30×100mm, 40×100mm, and 60×100mm.

We have the capability to produce both standard and custom-shaped steel grilles tailored to meet specific customer requirements.

Steel grating is a steel product formed by cross - welding flat steel and horizontal bars. It is extensively utilized in the production of manhole covers, steel structure platforms, and steel stair treads. With its capabilities of ventilation, lighting, heat dissipation, anti - slip, and explosion - proof features, it is well - suited for diverse industrial environments.

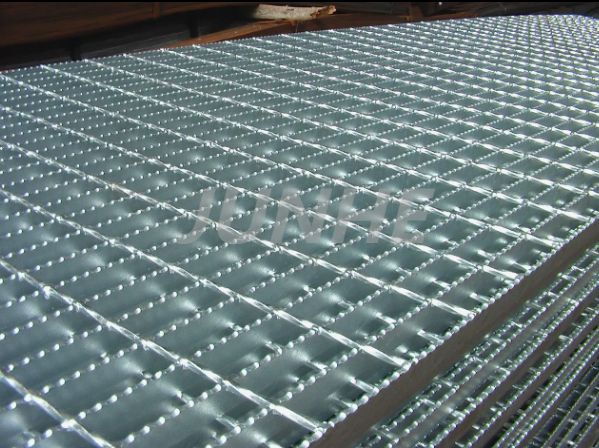

Outstanding Corrosion Resistance

Through the hot - dipping process, a thick zinc layer is formed on the surface of the steel grating. This layer serves as a protective barrier, effectively shielding the steel from rust and corrosion. It can withstand outdoor conditions for over 20 years, making it an excellent option for use in chemical plants and coastal areas.

High Strength and Load - Bearing Capacity

Made from high - grade steel bars with an optimized combination, a standard hot - dipped galvanized steel grating can bear loads ranging from 3 to 5 tons per square meter. This high strength makes it highly appropriate for heavy - duty industrial applications and areas with heavy traffic.

Superb Anti - Slip Performance

The distinct surface patterns of the steel grating increase friction. With an anti - slip coefficient exceeding 0.6, it greatly reduces the likelihood of slipping on wet or dusty walkways and stair treads, ensuring safety under various circumstances.

Easy Installation and Low Maintenance

The steel grating is prefabricated, enabling quick and straightforward installation using bolts or welding. This not only saves time and labor but also cuts down on installation costs. Furthermore, it requires minimal maintenance, with only occasional inspections needed to maintain its good condition, thereby reducing long - term operational expenses.

High Quality and Highly Customizable

Our factory follows stringent quality control procedures. Each batch of steel grating undergoes comprehensive and strict inspections to guarantee top - notch products. Moreover, we offer a high level of customization, allowing us to adjust the size, shape, and load - bearing capacity of the steel grating to meet specific customer needs, providing solutions for projects of all scales.

Q: How long can the hot - dipped galvanized steel grating last?

A: In normal outdoor conditions, it can last over 20 years due to the thick anti - corrosion zinc layer. But lifespan may vary in special environments like chemical plants.

Q: Can the steel grating be customized?

A: Absolutely. We can customize the size, shape, and load - bearing capacity according to your needs. Just let us know your specific requirements.

Q: What's the installation process like?

A: It's quite simple. First, align the grating accurately. Then, secure it using bolts or welding. Installation time is short, saving you both time and labor costs.

Q: How to maintain the hot - dipped galvanized steel grating?

A: Maintenance is easy. Just conduct occasional inspections. Since it has high corrosion resistance, there's no need for frequent upkeep. Only repair if any damage is found.

Hot-dip galvanized steel grating is widely used, typically seen in flooring, stair treads, and fencing. It is crafted from Q235 low-carbon steel or stainless steel.

The frequently used dimensions for load-bearing flat steel are 20×5mm, 25×5mm, and 30×3mm.

Horizontal bars commonly come in sizes of 5×5mm, 6×6mm, and 8×8mm.

The standard mesh sizes include 30×100mm, 40×100mm, and 60×100mm.

We have the capability to produce both standard and custom-shaped steel grilles tailored to meet specific customer requirements.

Steel grating is a steel product formed by cross - welding flat steel and horizontal bars. It is extensively utilized in the production of manhole covers, steel structure platforms, and steel stair treads. With its capabilities of ventilation, lighting, heat dissipation, anti - slip, and explosion - proof features, it is well - suited for diverse industrial environments.

Outstanding Corrosion Resistance

Through the hot - dipping process, a thick zinc layer is formed on the surface of the steel grating. This layer serves as a protective barrier, effectively shielding the steel from rust and corrosion. It can withstand outdoor conditions for over 20 years, making it an excellent option for use in chemical plants and coastal areas.

High Strength and Load - Bearing Capacity

Made from high - grade steel bars with an optimized combination, a standard hot - dipped galvanized steel grating can bear loads ranging from 3 to 5 tons per square meter. This high strength makes it highly appropriate for heavy - duty industrial applications and areas with heavy traffic.

Superb Anti - Slip Performance

The distinct surface patterns of the steel grating increase friction. With an anti - slip coefficient exceeding 0.6, it greatly reduces the likelihood of slipping on wet or dusty walkways and stair treads, ensuring safety under various circumstances.

Easy Installation and Low Maintenance

The steel grating is prefabricated, enabling quick and straightforward installation using bolts or welding. This not only saves time and labor but also cuts down on installation costs. Furthermore, it requires minimal maintenance, with only occasional inspections needed to maintain its good condition, thereby reducing long - term operational expenses.

High Quality and Highly Customizable

Our factory follows stringent quality control procedures. Each batch of steel grating undergoes comprehensive and strict inspections to guarantee top - notch products. Moreover, we offer a high level of customization, allowing us to adjust the size, shape, and load - bearing capacity of the steel grating to meet specific customer needs, providing solutions for projects of all scales.

Q: How long can the hot - dipped galvanized steel grating last?

A: In normal outdoor conditions, it can last over 20 years due to the thick anti - corrosion zinc layer. But lifespan may vary in special environments like chemical plants.

Q: Can the steel grating be customized?

A: Absolutely. We can customize the size, shape, and load - bearing capacity according to your needs. Just let us know your specific requirements.

Q: What's the installation process like?

A: It's quite simple. First, align the grating accurately. Then, secure it using bolts or welding. Installation time is short, saving you both time and labor costs.

Q: How to maintain the hot - dipped galvanized steel grating?

A: Maintenance is easy. Just conduct occasional inspections. Since it has high corrosion resistance, there's no need for frequent upkeep. Only repair if any damage is found.