- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

JunHe

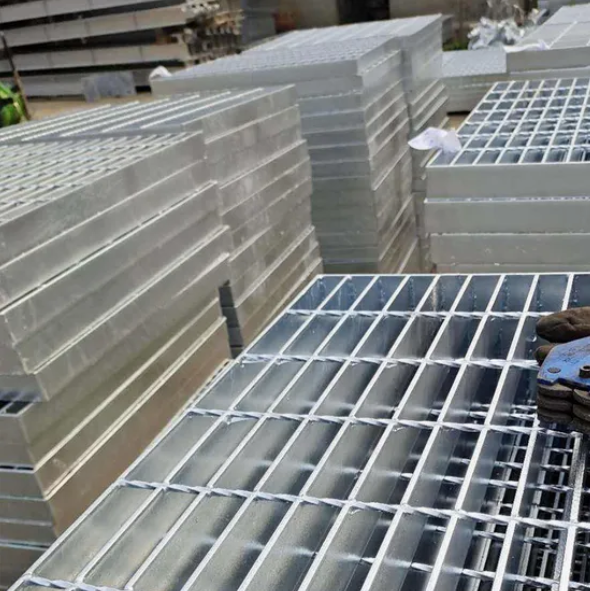

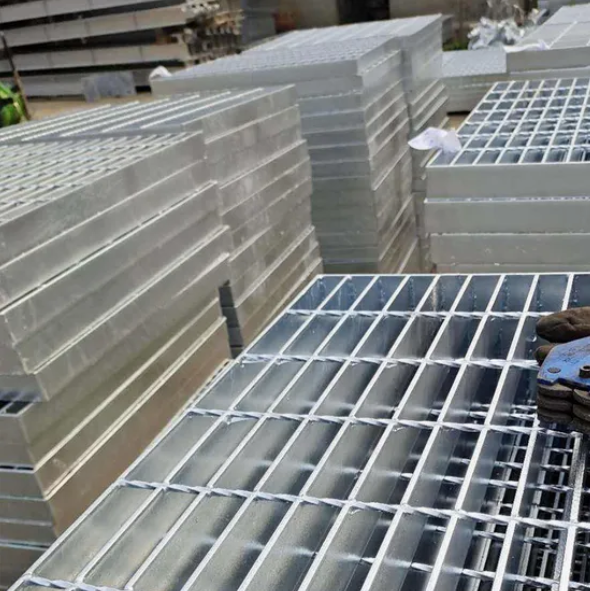

High-Strength Construction

Our drainage gratings are engineered from premium materials, including high-grade stainless steel and durable cast iron. Stainless steel models can withstand loads up to 8,000 kg, making them ideal for high-traffic zones like industrial parks and commercial driveways. This durability minimizes the need for frequent replacements, saving time and costs over time.

Exceptional Drainage Performance

Featuring a meticulously designed opening pattern, our gratings excel at managing water flow, handling up to 10,000 liters per minute. The optimized hole size and layout prevent debris-related blockages while enabling rapid water discharge—critical in flood-prone areas or regions with heavy rainfall.

Non-Slip Safety Surface

Safety is paramount. Our gratings are designed with a non-slip surface that maintains a friction coefficient of at least 0.75, even when wet from rain or industrial fluids. This significantly reduces slip and fall risks, making them suitable for pedestrian and vehicle traffic alike.

Customizable Design Flexibility

We recognize that projects have unique needs. Our gratings are available in diverse shapes (square, rectangular, circular) and sizes, with customizable hole patterns. For instance, we recently supplied slotted-design gratings for a modern architectural complex’s drainage system.

Corrosion Resistance

Built to withstand harsh environments, our gratings—particularly those made of stainless steel or treated with anti-corrosion coatings—resist salt, acid, and other corrosive substances for over 20 years with minimal degradation. This makes them ideal for coastal areas and chemical plants.

Load-Bearing Flat Steel: Choose Q235A carbon steel for cost-effective strength or stainless steel (304/316) for superior corrosion resistance.

Cross Bar: Available in Q235A or 304 stainless steel, with options including round, twisted square (5×5mm to 8×8mm), square, or hexagonal steel for enhanced stability.

Flat Steel: Thickness ranges from 3–10mm (e.g., 25×3mm to 100×10mm), with width adjusted to load requirements.

Grid: Center-to-center flat steel spacing options include 30/40/60mm; cross-bar spacing is 100/50mm.

Overall: Standard width is 995mm with a 5mm installation gap; customization is available.

Light-Duty: Supports 25 tons/m² for residential walkways, parks, and light-vehicle parking.

Medium-Duty: Rated at 70 tons/m² for factory floors and roads with vehicles under 20 tons.

Heavy-Duty: Handles 140 tons/m² for high-traffic zones like main roads and industrial docks.

Hot-Dip Galvanizing: 85μm zinc coating ensures over 20 years of lifespan under normal conditions.

Cold Galvanizing: Thinner coating for less demanding applications.

Painting: Anti-rust paint in multiple colors for aesthetics and corrosion protection.

Leakage Area: Up to 83.3%, enabling rapid water discharge.

Performance: Drains 1,000 liters/min/m² at a 50mm/h rainfall rate.

The embossed or coated surface provides a friction coefficient of at least 0.6 in wet or oily conditions, ensuring safety.

Urban Streets

Steel grilles installed in road gutters endure vehicle weights and drain rainwater swiftly, preventing waterlogging and ensuring traffic and pedestrian safety.

Industrial Plants

Corrosion-resistant gratings handle chemical spills in workshops and loading docks, while their durability supports heavy equipment traffic.

Commercial Buildings

Installed at mall entrances, parking lots, and basements, they effectively drain water and enhance safety with non-slip surfaces.

Residential Areas

For driveways and sidewalks, our gratings offer practical drainage with customizable designs to match aesthetic preferences.

Recreational Facilities

Around park fountains, playground walkways, and sports-field changing rooms, they maintain cleanliness and safety by quickly draining water.

Q: What's the lifespan of the steel grilles?

A: Our steel grilles, especially when hot - dip galvanized, can last over 20 years in normal conditions. Their robust material ensures long - term durability against wear and corrosion.

Q: Are they easy to install?

A: Yes. Standard - sized grilles come with a 5 - mm installation gap for easy fitting. They can be quickly placed in position. Custom - sized ones also have straightforward installation procedures.

Q: How to clean the grilles?

A: Regularly remove debris with a broom or shovel. For stubborn dirt or stains, use a mild detergent and water. In industrial settings, power - washing may be needed to handle heavy - duty grime.

Q: Can the grilles bear heavy loads?

A: Absolutely. They're designed with different load - bearing capacities. Heavy - duty grilles can withstand up to 140 tons/m², suitable for areas with heavy - truck traffic.

Q: Do you offer customization?

A: Yes, we provide customization in terms of size, shape, and hole patterns. This allows the grilles to meet specific project requirements, whether for aesthetics or functionality.

High-Strength Construction

Our drainage gratings are engineered from premium materials, including high-grade stainless steel and durable cast iron. Stainless steel models can withstand loads up to 8,000 kg, making them ideal for high-traffic zones like industrial parks and commercial driveways. This durability minimizes the need for frequent replacements, saving time and costs over time.

Exceptional Drainage Performance

Featuring a meticulously designed opening pattern, our gratings excel at managing water flow, handling up to 10,000 liters per minute. The optimized hole size and layout prevent debris-related blockages while enabling rapid water discharge—critical in flood-prone areas or regions with heavy rainfall.

Non-Slip Safety Surface

Safety is paramount. Our gratings are designed with a non-slip surface that maintains a friction coefficient of at least 0.75, even when wet from rain or industrial fluids. This significantly reduces slip and fall risks, making them suitable for pedestrian and vehicle traffic alike.

Customizable Design Flexibility

We recognize that projects have unique needs. Our gratings are available in diverse shapes (square, rectangular, circular) and sizes, with customizable hole patterns. For instance, we recently supplied slotted-design gratings for a modern architectural complex’s drainage system.

Corrosion Resistance

Built to withstand harsh environments, our gratings—particularly those made of stainless steel or treated with anti-corrosion coatings—resist salt, acid, and other corrosive substances for over 20 years with minimal degradation. This makes them ideal for coastal areas and chemical plants.

Load-Bearing Flat Steel: Choose Q235A carbon steel for cost-effective strength or stainless steel (304/316) for superior corrosion resistance.

Cross Bar: Available in Q235A or 304 stainless steel, with options including round, twisted square (5×5mm to 8×8mm), square, or hexagonal steel for enhanced stability.

Flat Steel: Thickness ranges from 3–10mm (e.g., 25×3mm to 100×10mm), with width adjusted to load requirements.

Grid: Center-to-center flat steel spacing options include 30/40/60mm; cross-bar spacing is 100/50mm.

Overall: Standard width is 995mm with a 5mm installation gap; customization is available.

Light-Duty: Supports 25 tons/m² for residential walkways, parks, and light-vehicle parking.

Medium-Duty: Rated at 70 tons/m² for factory floors and roads with vehicles under 20 tons.

Heavy-Duty: Handles 140 tons/m² for high-traffic zones like main roads and industrial docks.

Hot-Dip Galvanizing: 85μm zinc coating ensures over 20 years of lifespan under normal conditions.

Cold Galvanizing: Thinner coating for less demanding applications.

Painting: Anti-rust paint in multiple colors for aesthetics and corrosion protection.

Leakage Area: Up to 83.3%, enabling rapid water discharge.

Performance: Drains 1,000 liters/min/m² at a 50mm/h rainfall rate.

The embossed or coated surface provides a friction coefficient of at least 0.6 in wet or oily conditions, ensuring safety.

Urban Streets

Steel grilles installed in road gutters endure vehicle weights and drain rainwater swiftly, preventing waterlogging and ensuring traffic and pedestrian safety.

Industrial Plants

Corrosion-resistant gratings handle chemical spills in workshops and loading docks, while their durability supports heavy equipment traffic.

Commercial Buildings

Installed at mall entrances, parking lots, and basements, they effectively drain water and enhance safety with non-slip surfaces.

Residential Areas

For driveways and sidewalks, our gratings offer practical drainage with customizable designs to match aesthetic preferences.

Recreational Facilities

Around park fountains, playground walkways, and sports-field changing rooms, they maintain cleanliness and safety by quickly draining water.

Q: What's the lifespan of the steel grilles?

A: Our steel grilles, especially when hot - dip galvanized, can last over 20 years in normal conditions. Their robust material ensures long - term durability against wear and corrosion.

Q: Are they easy to install?

A: Yes. Standard - sized grilles come with a 5 - mm installation gap for easy fitting. They can be quickly placed in position. Custom - sized ones also have straightforward installation procedures.

Q: How to clean the grilles?

A: Regularly remove debris with a broom or shovel. For stubborn dirt or stains, use a mild detergent and water. In industrial settings, power - washing may be needed to handle heavy - duty grime.

Q: Can the grilles bear heavy loads?

A: Absolutely. They're designed with different load - bearing capacities. Heavy - duty grilles can withstand up to 140 tons/m², suitable for areas with heavy - truck traffic.

Q: Do you offer customization?

A: Yes, we provide customization in terms of size, shape, and hole patterns. This allows the grilles to meet specific project requirements, whether for aesthetics or functionality.