- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

JunHe

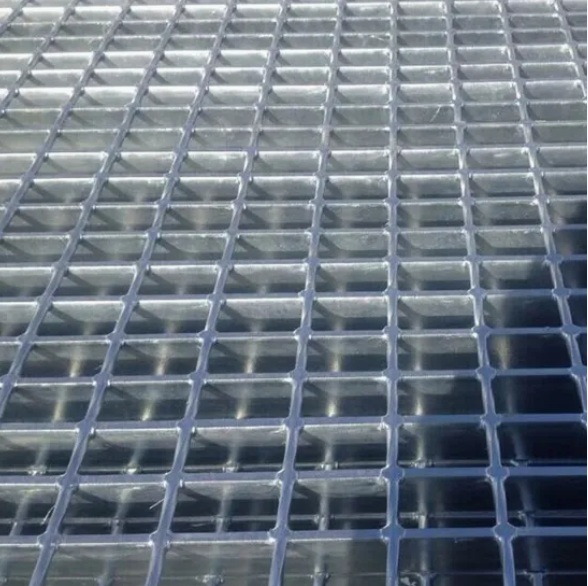

Exceptional Corrosion Resistance

The hot-dip process creates a thick zinc layer on the surface, preventing rust and corrosion. It can last over 20 years outdoors, making it ideal for chemical plants and coastal regions.

High Strength & Heavy Load Capacity

Made from premium steel bars with an optimized bar combination, a standard type can support 3 - 5 tons per square meter. Perfect for heavy-duty industrial and traffic zones.

Superior Anti-Slip Performance

Unique surface patterns boost friction. With an anti-slip coefficient above 0.6, it prevents slips on wet or dusty walkways and stair treads.

Effortless Installation & Low Maintenance

Pre-fabricated for quick installation using bolts or welding, saving time and labor. Requires minimal upkeep, just occasional checks to reduce long-term costs.

Top-Quality & Highly Customizable

Our factory adheres to strict quality checks. Each batch undergoes rigorous inspection for premium quality. We also customize size, shape, and load capacity to meet customer needs, offering solutions for projects of all sizes.

Material: Q235 low-carbon steel (good mechanical properties, affordable) or stainless steel (304, 316, excellent corrosion resistance for special environments).

Specification (Load-bearing Flat Bar × Cross Bar):

Load-bearing flat bars: 20×5, 25×5, 30×3, 30×5, 40×5, 50×5 mm, etc.

Cross bars: 5×5, 6×6, 8×8 mm, etc.

Different combinations meet various load-bearing demands.

Mesh Size:

Commonly used: 30×100, 40×100, 60×100 mm, etc.

Smaller meshes suit high-safety areas to prevent small object falls.

Larger meshes focus on ventilation, drainage, and cost-efficiency.

Galvanized Layer Thickness:

After hot-dipping, the average thickness is ≥85μm, and local thickness is ≥70μm.

Meets national standards for effective corrosion resistance and extended service life.

Bearing Capacity:

Varies by specification. For example, 303/30/100 steel grating has a uniform load of 3.5kN/m² and a concentrated load of 3.85kN.

Choose the right specification based on actual load requirements.

Surface Treatment:

Hot-dip galvanization forms a uniform, dense zinc layer for enhanced corrosion resistance.

Cold galvanization and painting are also available upon request.

Before installation, verify the size and quality of the hot-dipped galvanized steel grating. Align accurately and secure firmly with bolts or welding. In high-load areas, ensure the load stays within capacity. Regularly inspect for damage or corrosion. This straightforward process ensures long-term, safe use of the steel grating.

FAQ:

Q: How long can the hot - dipped galvanized steel grating last?

A: In normal outdoor conditions, it can last over 20 years due to the thick anti - corrosion zinc layer. But lifespan may vary in special environments like chemical plants.

Q: Can the steel grating be customized?

A: Absolutely. We can customize the size, shape, and load - bearing capacity according to your needs. Just let us know your specific requirements.

Q: What's the installation process like?

A: It's quite simple. First, align the grating accurately. Then, secure it using bolts or welding. Installation time is short, saving you both time and labor costs.

Q: How to maintain the hot - dipped galvanized steel grating?

A: Maintenance is easy. Just conduct occasional inspections. Since it has high corrosion resistance, there's no need for frequent upkeep. Only repair if any damage is found.

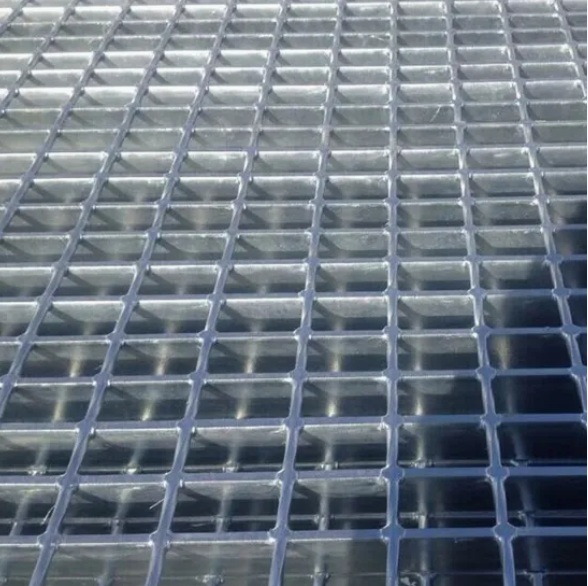

Exceptional Corrosion Resistance

The hot-dip process creates a thick zinc layer on the surface, preventing rust and corrosion. It can last over 20 years outdoors, making it ideal for chemical plants and coastal regions.

High Strength & Heavy Load Capacity

Made from premium steel bars with an optimized bar combination, a standard type can support 3 - 5 tons per square meter. Perfect for heavy-duty industrial and traffic zones.

Superior Anti-Slip Performance

Unique surface patterns boost friction. With an anti-slip coefficient above 0.6, it prevents slips on wet or dusty walkways and stair treads.

Effortless Installation & Low Maintenance

Pre-fabricated for quick installation using bolts or welding, saving time and labor. Requires minimal upkeep, just occasional checks to reduce long-term costs.

Top-Quality & Highly Customizable

Our factory adheres to strict quality checks. Each batch undergoes rigorous inspection for premium quality. We also customize size, shape, and load capacity to meet customer needs, offering solutions for projects of all sizes.

Material: Q235 low-carbon steel (good mechanical properties, affordable) or stainless steel (304, 316, excellent corrosion resistance for special environments).

Specification (Load-bearing Flat Bar × Cross Bar):

Load-bearing flat bars: 20×5, 25×5, 30×3, 30×5, 40×5, 50×5 mm, etc.

Cross bars: 5×5, 6×6, 8×8 mm, etc.

Different combinations meet various load-bearing demands.

Mesh Size:

Commonly used: 30×100, 40×100, 60×100 mm, etc.

Smaller meshes suit high-safety areas to prevent small object falls.

Larger meshes focus on ventilation, drainage, and cost-efficiency.

Galvanized Layer Thickness:

After hot-dipping, the average thickness is ≥85μm, and local thickness is ≥70μm.

Meets national standards for effective corrosion resistance and extended service life.

Bearing Capacity:

Varies by specification. For example, 303/30/100 steel grating has a uniform load of 3.5kN/m² and a concentrated load of 3.85kN.

Choose the right specification based on actual load requirements.

Surface Treatment:

Hot-dip galvanization forms a uniform, dense zinc layer for enhanced corrosion resistance.

Cold galvanization and painting are also available upon request.

Before installation, verify the size and quality of the hot-dipped galvanized steel grating. Align accurately and secure firmly with bolts or welding. In high-load areas, ensure the load stays within capacity. Regularly inspect for damage or corrosion. This straightforward process ensures long-term, safe use of the steel grating.

FAQ:

Q: How long can the hot - dipped galvanized steel grating last?

A: In normal outdoor conditions, it can last over 20 years due to the thick anti - corrosion zinc layer. But lifespan may vary in special environments like chemical plants.

Q: Can the steel grating be customized?

A: Absolutely. We can customize the size, shape, and load - bearing capacity according to your needs. Just let us know your specific requirements.

Q: What's the installation process like?

A: It's quite simple. First, align the grating accurately. Then, secure it using bolts or welding. Installation time is short, saving you both time and labor costs.

Q: How to maintain the hot - dipped galvanized steel grating?

A: Maintenance is easy. Just conduct occasional inspections. Since it has high corrosion resistance, there's no need for frequent upkeep. Only repair if any damage is found.