- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

JunHe

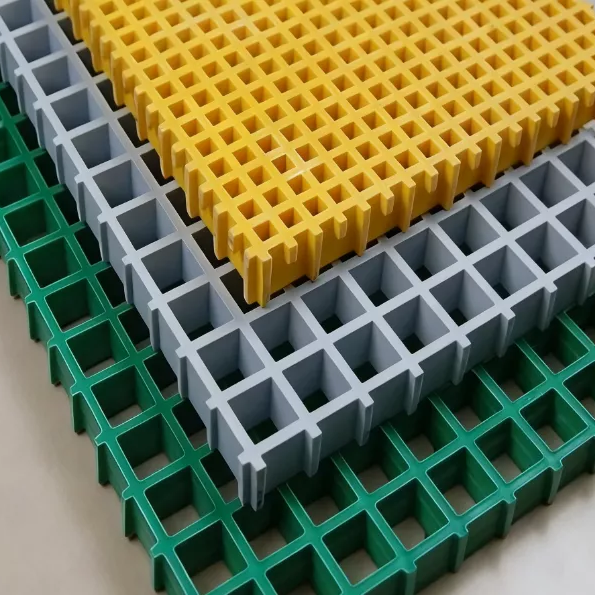

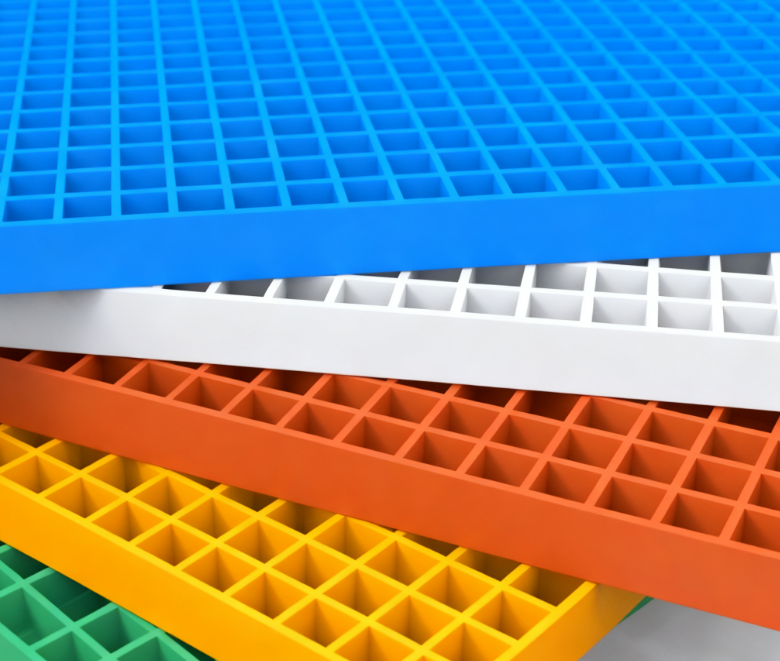

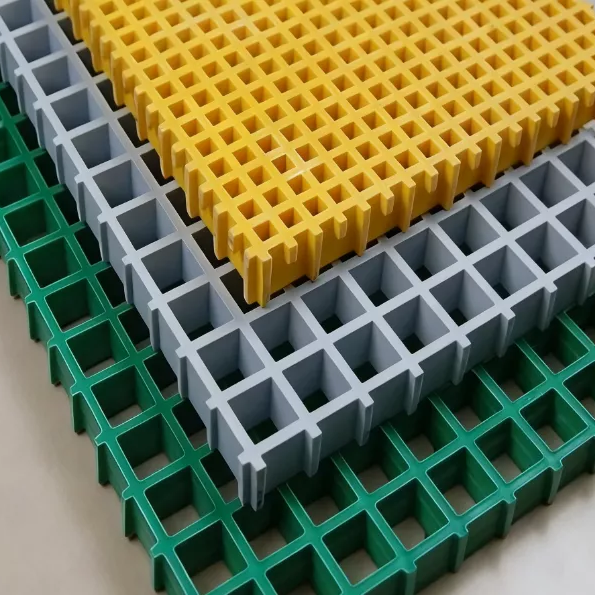

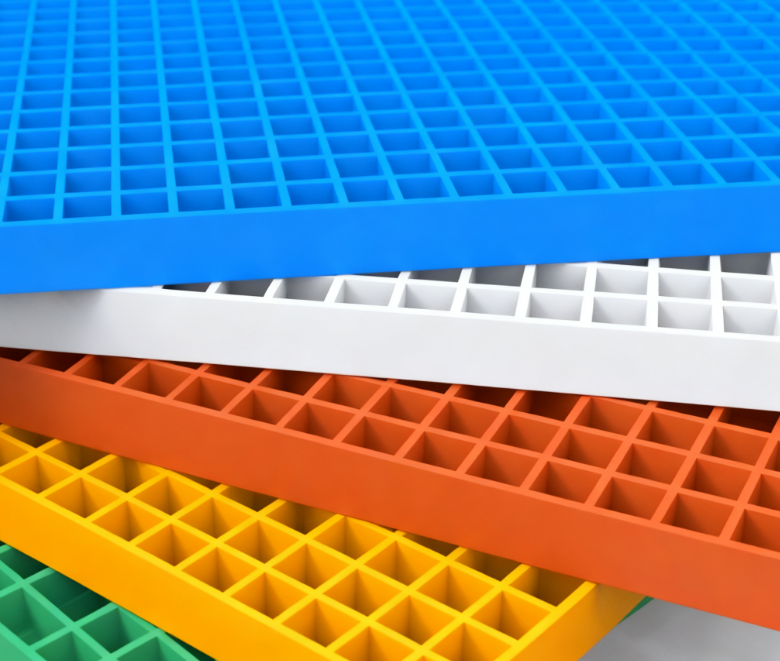

Fiberglass grating features a slip-resistant surface. Its textured finish achieves a friction coefficient as high as 0.6, which significantly lowers the risk of slips and falls. This feature is particularly important in safety-critical areas like stair treads and walkways in wet conditions.

The grating offers a high level of design flexibility. It can be customized into different sizes and shapes to meet the specific requirements of a project. Whether it’s a circular opening or a uniquely shaped platform, this adaptability ensures a perfect fit.

Length: The standard length is 1200mm, with a customizable range of 500–3000mm.

Width: Common widths are 600mm and 900mm, with a customizable range of 300–1500mm.

Thickness: Multiple thickness options are available, including 30mm, 38mm, and 50mm.

Uniform Load: Ranges from 3000–5000N/m², depending on thickness and structure.

Concentrated Load: The single-point concentrated load can reach 1000–2000N.

Crossbar Spacing: Typically 30mm and 40mm.

Longitudinal Bar Spacing: Common values are 40mm and 50mm.

Glass Fiber Content: Not less than 70%.

Resin Type: Includes unsaturated polyester resin, vinyl ester resin, etc.

Tensile Strength: Not less than 500MPa.

Bending Strength: Not less than 700MPa.

Anti-slip Treatment: The surface is equipped with a granular anti-slip layer, with a friction coefficient of at least 0.6.

Coating Treatment: An anti-corrosion coating can be applied, and the salt spray test time is at least 1000 hours.

Fire-Retardant Grade: Meets the UL94-V0 level (flame-retardant grade).

The offshore environment is extremely harsh, but fiberglass grating is well-suited for use on offshore operation platforms. It is resistant to seawater corrosion and ultraviolet rays, and can withstand the impact of ocean waves and the heavy pressure of equipment, providing a safe and stable working space for offshore operations.

1. What is the lifespan of FIBERGLASS GRATING?

Under normal conditions, its lifespan can reach over 20 years. This is due to its corrosion - resistant materials and stable structure, ensuring long - term use without significant degradation.

2. Can FIBERGLASS GRATING be customized?

Absolutely. We offer customization services. You can tell us your specific requirements regarding size, shape, and surface treatment. Our team will tailor the product to meet your needs precisely.

3. How do you ensure the quality of FIBERGLASS GRATING?

We have strict quality control processes. Raw materials are carefully selected, and each production step is monitored. Products undergo multiple tests, like load - bearing and corrosion resistance tests, to guarantee high - quality output.

Fiberglass grating features a slip-resistant surface. Its textured finish achieves a friction coefficient as high as 0.6, which significantly lowers the risk of slips and falls. This feature is particularly important in safety-critical areas like stair treads and walkways in wet conditions.

The grating offers a high level of design flexibility. It can be customized into different sizes and shapes to meet the specific requirements of a project. Whether it’s a circular opening or a uniquely shaped platform, this adaptability ensures a perfect fit.

Length: The standard length is 1200mm, with a customizable range of 500–3000mm.

Width: Common widths are 600mm and 900mm, with a customizable range of 300–1500mm.

Thickness: Multiple thickness options are available, including 30mm, 38mm, and 50mm.

Uniform Load: Ranges from 3000–5000N/m², depending on thickness and structure.

Concentrated Load: The single-point concentrated load can reach 1000–2000N.

Crossbar Spacing: Typically 30mm and 40mm.

Longitudinal Bar Spacing: Common values are 40mm and 50mm.

Glass Fiber Content: Not less than 70%.

Resin Type: Includes unsaturated polyester resin, vinyl ester resin, etc.

Tensile Strength: Not less than 500MPa.

Bending Strength: Not less than 700MPa.

Anti-slip Treatment: The surface is equipped with a granular anti-slip layer, with a friction coefficient of at least 0.6.

Coating Treatment: An anti-corrosion coating can be applied, and the salt spray test time is at least 1000 hours.

Fire-Retardant Grade: Meets the UL94-V0 level (flame-retardant grade).

The offshore environment is extremely harsh, but fiberglass grating is well-suited for use on offshore operation platforms. It is resistant to seawater corrosion and ultraviolet rays, and can withstand the impact of ocean waves and the heavy pressure of equipment, providing a safe and stable working space for offshore operations.

1. What is the lifespan of FIBERGLASS GRATING?

Under normal conditions, its lifespan can reach over 20 years. This is due to its corrosion - resistant materials and stable structure, ensuring long - term use without significant degradation.

2. Can FIBERGLASS GRATING be customized?

Absolutely. We offer customization services. You can tell us your specific requirements regarding size, shape, and surface treatment. Our team will tailor the product to meet your needs precisely.

3. How do you ensure the quality of FIBERGLASS GRATING?

We have strict quality control processes. Raw materials are carefully selected, and each production step is monitored. Products undergo multiple tests, like load - bearing and corrosion resistance tests, to guarantee high - quality output.