- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

JunHe

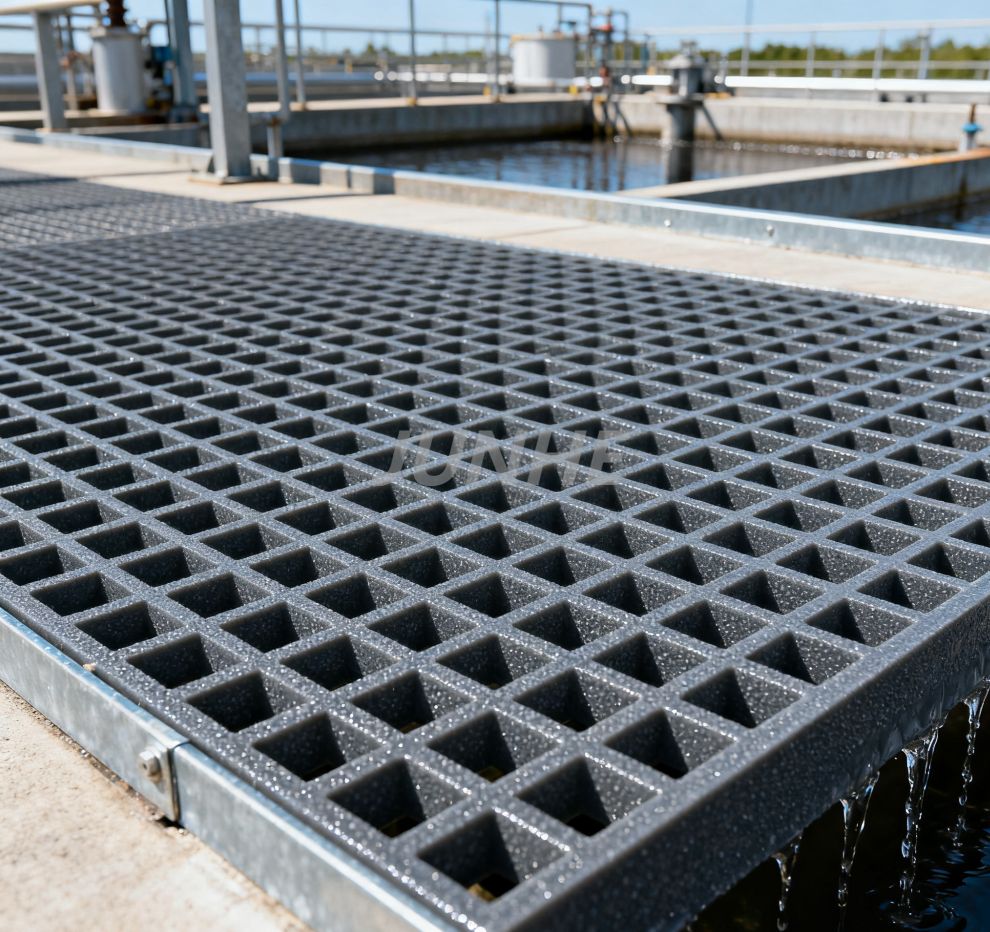

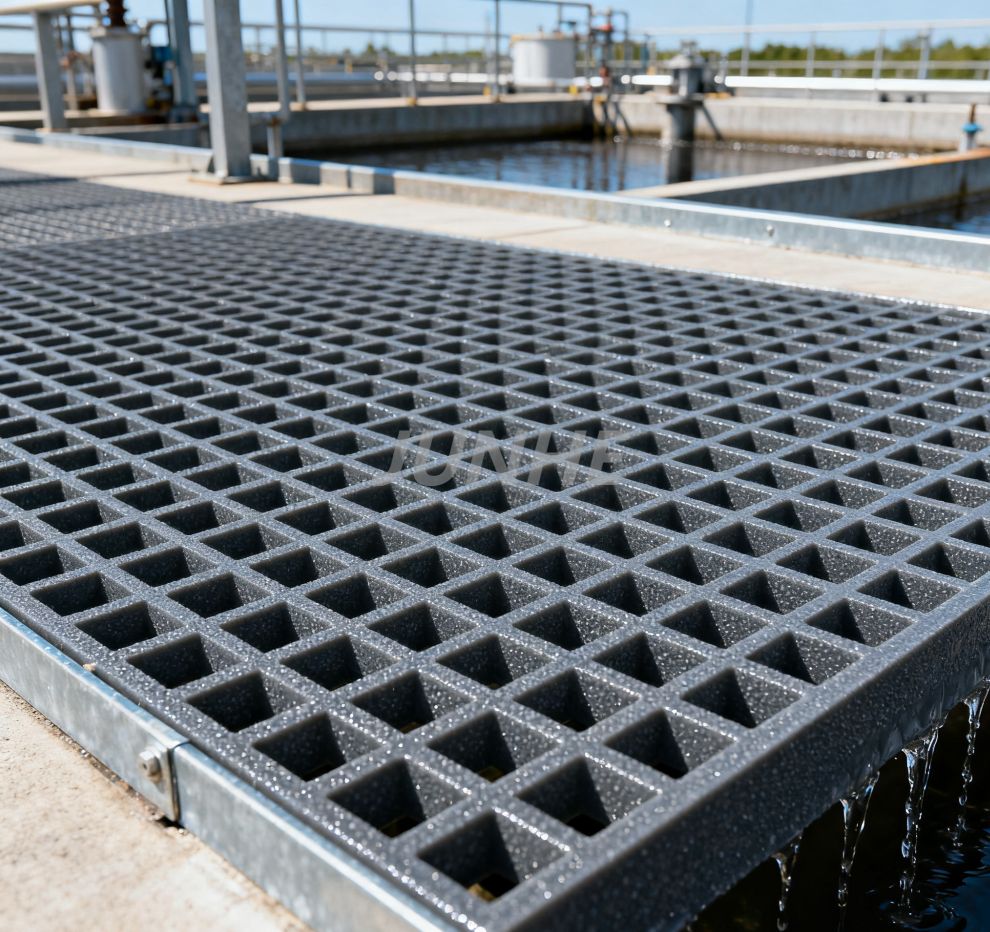

Unlike traditional metal gratings, fiberglass is inherently resistant to rust and corrosion. This characteristic makes it an outstanding choice for settings such as chemical plants and wastewater treatment facilities, where frequent contact with corrosive substances is inevitable.

Fiberglass grating offers remarkable strength. Made from top - quality glass fibers, it has an excellent load - bearing capacity. Specifically, it can bear up to 3000 pounds per square foot, making it highly appropriate for applications like industrial walkways and platforms that require long - lasting durability.

This grating shows great resistance to a broad range of chemicals, including acids and alkalis. Laboratory experiments have indicated that it remains intact after being immersed in a 10% sulfuric acid solution for more than 1000 hours. This feature makes it a perfect option for chemical plants and wastewater treatment facilities.

The surface of fiberglass grating is designed to prevent slipping. Its texture gives it a friction coefficient as high as 0.6, greatly reducing the chance of slips and falls. This is especially crucial in safety - sensitive areas such as stair treads and wet walkways.

Fiberglass grating is both lightweight and highly durable. Compared to a steel grating with the same specifications, it weighs only one - quarter as much, and its service life can exceed 20 years. This combination of light weight and durability makes the installation process easier and provides long - term cost savings.

The grating offers a great deal of design flexibility. It can be tailored to different sizes and shapes according to the specific needs of a project. Whether it's a circular opening or a uniquely shaped platform, its adaptability ensures a precise fit.

Length: The standard length is 1200mm, and it can be customized within the range of 500 - 3000mm.

Width: Common widths are 600mm and 900mm, with a customizable range of 300 - 1500mm.

Thickness: There are multiple thickness options, including 30mm, 38mm, and 50mm.

Uniform Load: It ranges from 3000 - 5000N/m², depending on different thicknesses and structures.

Concentrated Load: The single - point concentrated load can reach 1000 - 2000N.

Crossbar Spacing: Typically, it is 30mm and 40mm.

Longitudinal Bar Spacing: Common values are 40mm and 50mm.

Glass Fiber Content: It should be no less than 70%.

Resin Type: Includes unsaturated polyester resin, vinyl ester resin, etc.

Tensile Strength: It should be no less than 500MPa.

Bending Strength: It should be no less than 700MPa.

Anti - slip Treatment: The surface has a granular anti - slip layer with a friction coefficient of at least 0.6.

Coating Treatment: An anti - corrosion coating can be applied, and it should pass a salt spray test for at least 1000 hours.

Fire - Retardant Grade: It achieves the UL94 - V0 level (flame - retardant grade).

In factory workshops, fiberglass grating is widely used to build operating platforms. Its high strength can support equipment and workers during operations, and its corrosion - resistant properties enable it to endure chemical substances in the industrial setting. This ensures the stable long - term operation of the platform, improving work safety and efficiency.

Fiberglass grating is also used in building stairs. Its slip - resistant surface effectively minimizes the risk of slipping. The lightweight nature of the material simplifies the installation process, reducing construction complexity and cost. Moreover, its aesthetic appeal and durability make it suitable for various architectural styles.

In sewage treatment plants, fiberglass grating is used for gratings and walkways. Its excellent resistance to acids and alkalis allows it to function effectively in the highly corrosive sewage environment, ensuring the reliable long - term operation of the facilities.

In power substations and other locations, fiberglass grating is often used for maintenance walkways. It is insulating and has high strength, ensuring the safety of maintenance personnel. Even in harsh weather conditions, it can stably support the weight of people walking.

The offshore environment is extremely challenging, but fiberglass grating is well - suited for offshore operation platforms. It is resistant to seawater corrosion and ultraviolet rays, and can withstand the impact of ocean waves and the heavy pressure of equipment, providing a safe and stable working space for offshore operations.

1. What is the lifespan of FIBERGLASS GRATING?

Under normal conditions, its lifespan can reach over 20 years. This is due to its corrosion - resistant materials and stable structure, ensuring long - term use without significant degradation.

2. Can FIBERGLASS GRATING be customized?

Absolutely. We offer customization services. You can tell us your specific requirements regarding size, shape, and surface treatment. Our team will tailor the product to meet your needs precisely.

3. How do you ensure the quality of FIBERGLASS GRATING?

We have strict quality control processes. Raw materials are carefully selected, and each production step is monitored. Products undergo multiple tests, like load - bearing and corrosion resistance tests, to guarantee high - quality output.

Unlike traditional metal gratings, fiberglass is inherently resistant to rust and corrosion. This characteristic makes it an outstanding choice for settings such as chemical plants and wastewater treatment facilities, where frequent contact with corrosive substances is inevitable.

Fiberglass grating offers remarkable strength. Made from top - quality glass fibers, it has an excellent load - bearing capacity. Specifically, it can bear up to 3000 pounds per square foot, making it highly appropriate for applications like industrial walkways and platforms that require long - lasting durability.

This grating shows great resistance to a broad range of chemicals, including acids and alkalis. Laboratory experiments have indicated that it remains intact after being immersed in a 10% sulfuric acid solution for more than 1000 hours. This feature makes it a perfect option for chemical plants and wastewater treatment facilities.

The surface of fiberglass grating is designed to prevent slipping. Its texture gives it a friction coefficient as high as 0.6, greatly reducing the chance of slips and falls. This is especially crucial in safety - sensitive areas such as stair treads and wet walkways.

Fiberglass grating is both lightweight and highly durable. Compared to a steel grating with the same specifications, it weighs only one - quarter as much, and its service life can exceed 20 years. This combination of light weight and durability makes the installation process easier and provides long - term cost savings.

The grating offers a great deal of design flexibility. It can be tailored to different sizes and shapes according to the specific needs of a project. Whether it's a circular opening or a uniquely shaped platform, its adaptability ensures a precise fit.

Length: The standard length is 1200mm, and it can be customized within the range of 500 - 3000mm.

Width: Common widths are 600mm and 900mm, with a customizable range of 300 - 1500mm.

Thickness: There are multiple thickness options, including 30mm, 38mm, and 50mm.

Uniform Load: It ranges from 3000 - 5000N/m², depending on different thicknesses and structures.

Concentrated Load: The single - point concentrated load can reach 1000 - 2000N.

Crossbar Spacing: Typically, it is 30mm and 40mm.

Longitudinal Bar Spacing: Common values are 40mm and 50mm.

Glass Fiber Content: It should be no less than 70%.

Resin Type: Includes unsaturated polyester resin, vinyl ester resin, etc.

Tensile Strength: It should be no less than 500MPa.

Bending Strength: It should be no less than 700MPa.

Anti - slip Treatment: The surface has a granular anti - slip layer with a friction coefficient of at least 0.6.

Coating Treatment: An anti - corrosion coating can be applied, and it should pass a salt spray test for at least 1000 hours.

Fire - Retardant Grade: It achieves the UL94 - V0 level (flame - retardant grade).

In factory workshops, fiberglass grating is widely used to build operating platforms. Its high strength can support equipment and workers during operations, and its corrosion - resistant properties enable it to endure chemical substances in the industrial setting. This ensures the stable long - term operation of the platform, improving work safety and efficiency.

Fiberglass grating is also used in building stairs. Its slip - resistant surface effectively minimizes the risk of slipping. The lightweight nature of the material simplifies the installation process, reducing construction complexity and cost. Moreover, its aesthetic appeal and durability make it suitable for various architectural styles.

In sewage treatment plants, fiberglass grating is used for gratings and walkways. Its excellent resistance to acids and alkalis allows it to function effectively in the highly corrosive sewage environment, ensuring the reliable long - term operation of the facilities.

In power substations and other locations, fiberglass grating is often used for maintenance walkways. It is insulating and has high strength, ensuring the safety of maintenance personnel. Even in harsh weather conditions, it can stably support the weight of people walking.

The offshore environment is extremely challenging, but fiberglass grating is well - suited for offshore operation platforms. It is resistant to seawater corrosion and ultraviolet rays, and can withstand the impact of ocean waves and the heavy pressure of equipment, providing a safe and stable working space for offshore operations.

1. What is the lifespan of FIBERGLASS GRATING?

Under normal conditions, its lifespan can reach over 20 years. This is due to its corrosion - resistant materials and stable structure, ensuring long - term use without significant degradation.

2. Can FIBERGLASS GRATING be customized?

Absolutely. We offer customization services. You can tell us your specific requirements regarding size, shape, and surface treatment. Our team will tailor the product to meet your needs precisely.

3. How do you ensure the quality of FIBERGLASS GRATING?

We have strict quality control processes. Raw materials are carefully selected, and each production step is monitored. Products undergo multiple tests, like load - bearing and corrosion resistance tests, to guarantee high - quality output.