- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

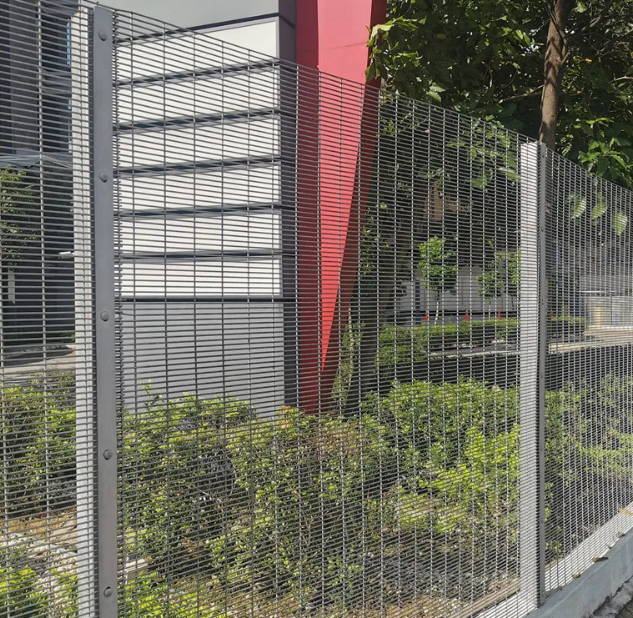

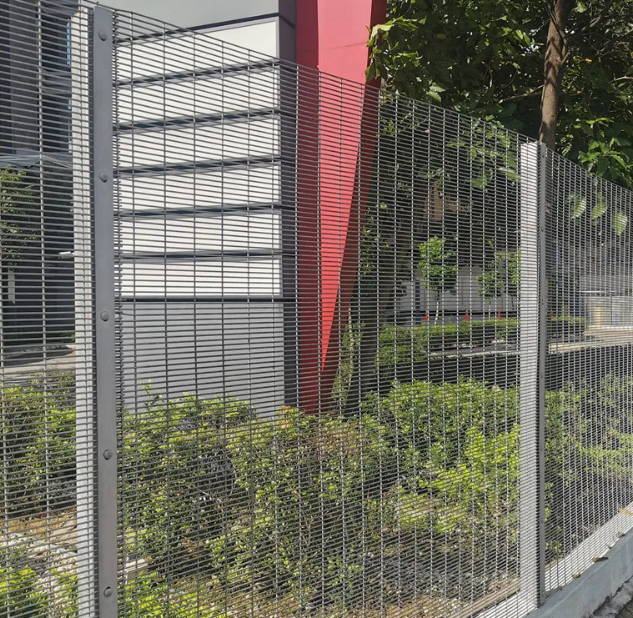

358 High Security Fence - The Benchmark Solution for Global High Security Scene Protection

As a special protective fence designed specifically for high security scenarios such as military fortresses, prisons, nuclear power plants, and data centers, the 358 fence has become a benchmark product in the global security field due to its unique structural design and excellent performance. Its name "358" is directly derived from the core parameters: horizontal grid spacing of 76mm (3 inches), vertical grid spacing of 12mm (0.5 inches), woven with No. 8 steel wire (diameter of about 4mm) to construct a dense and sturdy protective network.

Excellent protective performance, reshaping the safety benchmark

Anti climbing breakthrough design: 76mm × 12mm precision mesh effectively blocks finger grip, combined with 3-5mm anti shear steel wire, completely eliminating climbing, cutting and other invasive behaviors. The top can be integrated with a Y-shaped anti climbing device or a snake belly type knife stab net, forming a three-dimensional protective system.

Stable and impact resistant structure: Made of Q235 low-carbon steel wire that has been cold drawn, with a tensile strength exceeding 500MPa. The frame is reinforced with rectangular steel pipes and equipped with pre embedded anchor bolts, which can withstand wind impact of level 8 and earthquake intensity of level 8, ensuring extreme environmental stability.

Long term anti-corrosion upgrade: Provides dual protective coatings of galvanizing+dipping/spraying, with no red rust after 1000 hours of salt spray testing. Optional PVDF fluorocarbon coating, with a lifespan of up to 25 years in coastal high salt spray and industrial corrosive environments.

Full dimensional customization and adaptation to meet diverse scene requirements

Flexible size customization: Height coverage of 1.5-4 meters (regular 2/2.5/3 meters), standard board width of 2-3 meters, supporting non-standard size customization. The 4-meter ultra-high version is designed specifically for airport isolation and border protection.

Color Aesthetics System: We offer standard color schemes such as dark green, gray white, police blue, desert yellow, and can also customize camouflage coatings or enterprise exclusive colors to balance concealment and recognition needs.

Modular installation system: adopting bolt connection+welding dual process, with a single board weight of about 55kg, matched with prefabricated concrete base or quick installation bracket, greatly improving construction efficiency.

Analysis of Deep Technical Parameters

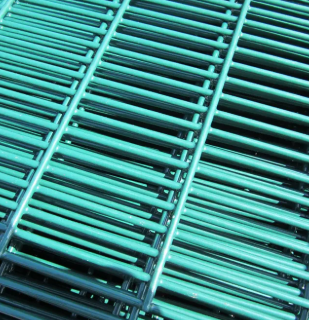

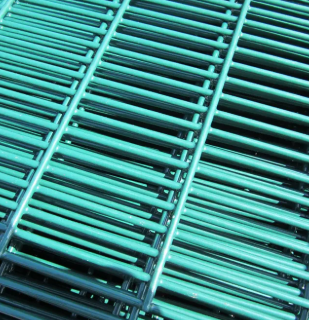

Core material: Low carbon steel wire with balanced strength and ductility

Grid accuracy: Laser cutting ensures zero error in the size of 76mm × 12mm, with excellent flatness of the board surface

Coating process: covering various solutions such as galvanizing, spraying, dipping, and PVC spraying

Scenario extension application

Military stronghold: ammunition depot, command center, three-dimensional protection

Judicial system: prison/detention center anti escape barrier

Energy facilities: perimeter protection for power plants and oil depots

Transportation hub: airport, station isolation zone

High end property: villa area, industrial park intelligent enclosure

Installation and Maintenance Guide

It is recommended to use a concrete pouring base and pre embedded steel plate connection, combined with an electronic fence alarm system to achieve dual protection of civil defense and technical defense. Daily maintenance only requires rinsing with clean water, and the damaged coating can be partially repaired, effectively extending the overall service life.

Choosing the 358 anti climbing fence means choosing a security solution that has been validated by over 3000 major projects worldwide. From Alaska's extreme cold base to Middle Eastern desert prisons, from Nordic data centers to Southeast Asian port facilities, the 358 fence is built with rigorous craftsmanship standards to create an impeccable security line. Customize exclusive protection plans immediately, making professional security within reach.

FAQS:

Q1: What is the meaning of the name?

Horizontal spacing of 3 inches (76mm), vertical spacing of 0.5 inches (12mm), and No. 8 steel wire (4mm) form a high-density anti climbing grid.

Q2: Anti climbing principle?

The fine mesh prevents grasping, the thick steel wire is resistant to cutting, and the top can be equipped with anti climbing/blade piercing ropes, providing triple protection against intrusion.

Q3: Applicable scenarios?

High security places such as military bases, prisons, and nuclear power plants; More resistant to climbing than peach shaped fences, but at a higher cost.

Q4: How long can it be used?

Galvanized+dip coated, salt spray test for over 1000 hours without rusting; PVDF coating for coastal environments, with a lifespan of 25 years.

Q5: Size and installation?

Customizable height of 1.5-4 meters, standard board width of 2-3 meters; Modular installation, daily installation of 200 meters, recommended bolt+welding fixation.

Q6: Color selection?

Standard colors such as dark green, gray white, etc. can be customized with camouflage or corporate colors; Use dark colors for concealed scenes and bright colors for identification scenes.

Q7: Maintenance costs?

Rinse with clean water, inspect the coating every six months, repair any damages, and have low long-term costs.

Q8: How to choose specifications?

Select a high-risk scenario with a height of 4 meters, 5mm thick wire, and double coating; Low risk selection of 2-3 meters+3-4mm wire+single coating requires professional evaluation.

358 High Security Fence - The Benchmark Solution for Global High Security Scene Protection

As a special protective fence designed specifically for high security scenarios such as military fortresses, prisons, nuclear power plants, and data centers, the 358 fence has become a benchmark product in the global security field due to its unique structural design and excellent performance. Its name "358" is directly derived from the core parameters: horizontal grid spacing of 76mm (3 inches), vertical grid spacing of 12mm (0.5 inches), woven with No. 8 steel wire (diameter of about 4mm) to construct a dense and sturdy protective network.

Excellent protective performance, reshaping the safety benchmark

Anti climbing breakthrough design: 76mm × 12mm precision mesh effectively blocks finger grip, combined with 3-5mm anti shear steel wire, completely eliminating climbing, cutting and other invasive behaviors. The top can be integrated with a Y-shaped anti climbing device or a snake belly type knife stab net, forming a three-dimensional protective system.

Stable and impact resistant structure: Made of Q235 low-carbon steel wire that has been cold drawn, with a tensile strength exceeding 500MPa. The frame is reinforced with rectangular steel pipes and equipped with pre embedded anchor bolts, which can withstand wind impact of level 8 and earthquake intensity of level 8, ensuring extreme environmental stability.

Long term anti-corrosion upgrade: Provides dual protective coatings of galvanizing+dipping/spraying, with no red rust after 1000 hours of salt spray testing. Optional PVDF fluorocarbon coating, with a lifespan of up to 25 years in coastal high salt spray and industrial corrosive environments.

Full dimensional customization and adaptation to meet diverse scene requirements

Flexible size customization: Height coverage of 1.5-4 meters (regular 2/2.5/3 meters), standard board width of 2-3 meters, supporting non-standard size customization. The 4-meter ultra-high version is designed specifically for airport isolation and border protection.

Color Aesthetics System: We offer standard color schemes such as dark green, gray white, police blue, desert yellow, and can also customize camouflage coatings or enterprise exclusive colors to balance concealment and recognition needs.

Modular installation system: adopting bolt connection+welding dual process, with a single board weight of about 55kg, matched with prefabricated concrete base or quick installation bracket, greatly improving construction efficiency.

Analysis of Deep Technical Parameters

Core material: Low carbon steel wire with balanced strength and ductility

Grid accuracy: Laser cutting ensures zero error in the size of 76mm × 12mm, with excellent flatness of the board surface

Coating process: covering various solutions such as galvanizing, spraying, dipping, and PVC spraying

Scenario extension application

Military stronghold: ammunition depot, command center, three-dimensional protection

Judicial system: prison/detention center anti escape barrier

Energy facilities: perimeter protection for power plants and oil depots

Transportation hub: airport, station isolation zone

High end property: villa area, industrial park intelligent enclosure

Installation and Maintenance Guide

It is recommended to use a concrete pouring base and pre embedded steel plate connection, combined with an electronic fence alarm system to achieve dual protection of civil defense and technical defense. Daily maintenance only requires rinsing with clean water, and the damaged coating can be partially repaired, effectively extending the overall service life.

Choosing the 358 anti climbing fence means choosing a security solution that has been validated by over 3000 major projects worldwide. From Alaska's extreme cold base to Middle Eastern desert prisons, from Nordic data centers to Southeast Asian port facilities, the 358 fence is built with rigorous craftsmanship standards to create an impeccable security line. Customize exclusive protection plans immediately, making professional security within reach.

FAQS:

Q1: What is the meaning of the name?

Horizontal spacing of 3 inches (76mm), vertical spacing of 0.5 inches (12mm), and No. 8 steel wire (4mm) form a high-density anti climbing grid.

Q2: Anti climbing principle?

The fine mesh prevents grasping, the thick steel wire is resistant to cutting, and the top can be equipped with anti climbing/blade piercing ropes, providing triple protection against intrusion.

Q3: Applicable scenarios?

High security places such as military bases, prisons, and nuclear power plants; More resistant to climbing than peach shaped fences, but at a higher cost.

Q4: How long can it be used?

Galvanized+dip coated, salt spray test for over 1000 hours without rusting; PVDF coating for coastal environments, with a lifespan of 25 years.

Q5: Size and installation?

Customizable height of 1.5-4 meters, standard board width of 2-3 meters; Modular installation, daily installation of 200 meters, recommended bolt+welding fixation.

Q6: Color selection?

Standard colors such as dark green, gray white, etc. can be customized with camouflage or corporate colors; Use dark colors for concealed scenes and bright colors for identification scenes.

Q7: Maintenance costs?

Rinse with clean water, inspect the coating every six months, repair any damages, and have low long-term costs.

Q8: How to choose specifications?

Select a high-risk scenario with a height of 4 meters, 5mm thick wire, and double coating; Low risk selection of 2-3 meters+3-4mm wire+single coating requires professional evaluation.