- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

As a benchmark product for high-security scenarios, the 358 anti-climb fence's technical specifications and performance advantages are fully demonstrated through the following structured analysis:

Core Parameters and Protection Principle

Naming Logic:

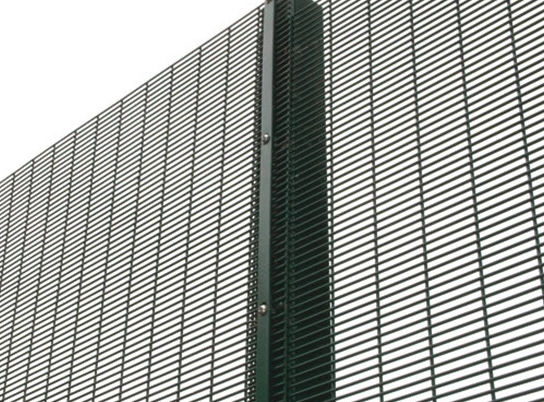

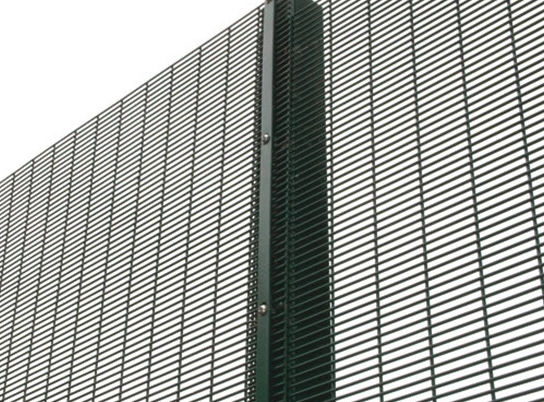

The high-density grid structure, constructed with 3-inch (76mm) horizontal reinforcement spacing, 0.5-inch (12mm) vertical reinforcement spacing, and No. 8 steel wire (4mm diameter), directly physically blocks intrusions such as climbing and cutting.

Anti-climb Mechanism:

The 76mm x 12mm precision grid effectively reduces finger grip space, while combined with 3-5mm shear-resistant steel wire, it provides dual physical protection.

The top can be integrated with a Y-shaped anti-climb bracket or accordion-type barbed wire to create a three-dimensional protective network.

The cold-drawn Q235 low-carbon steel wire (tensile strength ≥500MPa) undergoes a triple anti-corrosion treatment process of galvanizing, plastic dipping, and spray coating, resulting in over 1000 hours of rust-free salt spray testing. The PVDF fluorocarbon coating has a service life of up to 25 years in coastal high-salt spray environments.

Structural Performance and Customization Capabilities

Stability Design:

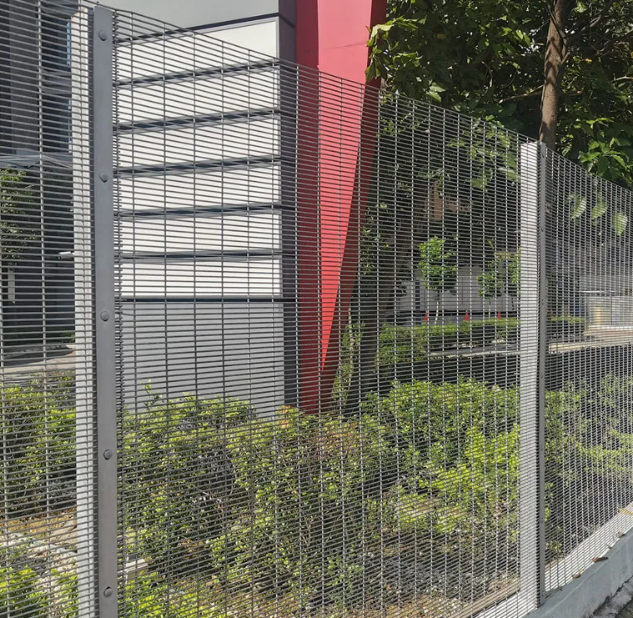

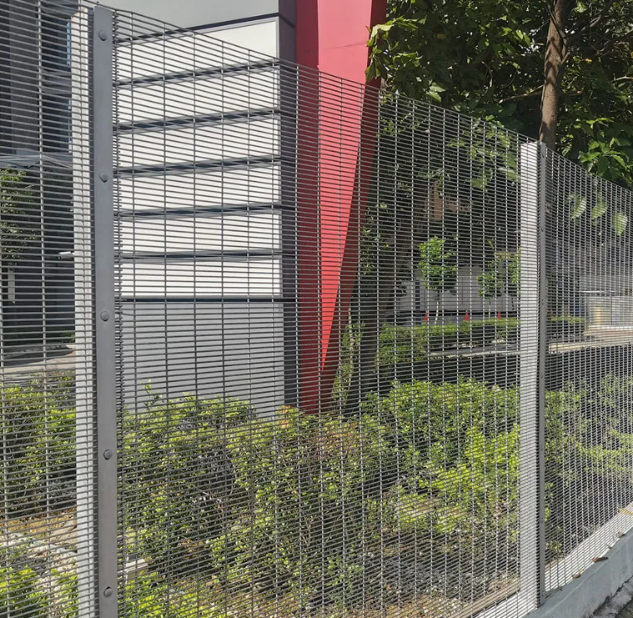

The rectangular steel tube frame strengthens the structural support and is secured with anchor bolts, capable of withstanding wind loads of magnitude 8 and impacts in earthquake zones of magnitude 8.

The modular installation system utilizes a dual bolting and welding process, enabling rapid assembly of individual panels, with a daily construction capacity of up to 200 meters. It is compatible with concrete foundations or quick-install brackets.

Dimensions and Customization:

Heights range from 1.5 to 4 meters (the super-high-rise 4-meter version is designed for airport and border isolation), with standard panel widths of 2 to 3 meters. Custom sizes are also supported.

The color palette includes standard colors such as dark green, grayish white, police blue, and desert yellow, with camouflage paint or corporate colors available to balance concealment and visual recognition.

Application Scenarios and Cost-Effectiveness

Suitable for High-Risk Scenarios:

Military locations (ammunition depots, command centers), judicial systems (prisons/detention centers), energy facilities (power plants/oil depots), transportation hubs (airport/station isolation zones), and high-end properties (villa complexes/industrial parks).

Compared to peach-shaped fences, 358 fences offer superior climb resistance, but are more expensive.

Specifications should be selected based on the risk level (e.g., 4 meters high with 5mm steel wire and double coating are recommended for high-risk scenarios, while 2-3 meters with 3-4mm steel wire and single coating are recommended for low-risk scenarios).

Maintenance and Lifespan:

Daily maintenance requires only water rinsing, and coating damage can be partially repaired, significantly extending service life.

Combined with an electronic fence alarm system, it provides dual security protection, both physical and technical.

Technical Parameters in Depth

Material Processing: Low-carbon steel wire is cold-drawn to achieve the optimal balance between strength and ductility. Laser cutting ensures grid precision (76mm x 12mm), minimal error, and excellent flatness.

Coating System: Utilizing a combined galvanizing, plastic dipping, and spraying process, with optional PVDF fluorocarbon coating, it adapts to the corrosion requirements of various environments.

Global Case Verification

Proven in over 3,000 major projects worldwide, from Alaska's arctic bases to Middle Eastern desert prisons, from Nordic data centers to Southeast Asian port facilities, our rigorous engineering standards ensure an impeccable security perimeter.

Summary

Choosing 358 anti-climb fencing means choosing a proven protection solution proven in high-security scenarios worldwide. With comprehensive customization options for size, color, and installation methods, it can precisely adapt to diverse scenarios, including military, judicial, energy, transportation, and high-end real estate, ensuring professional-grade security. For customized protection plans, we can optimize the specifications, configuration, and installation plan based on specific scenario risk assessments.

FAQS:

Q1: What is the meaning of the name?

Horizontal spacing of 3 inches (76mm), vertical spacing of 0.5 inches (12mm), and No. 8 steel wire (4mm) form a high-density anti climbing grid.

Q2: Anti climbing principle?

The fine mesh prevents grasping, the thick steel wire is resistant to cutting, and the top can be equipped with anti climbing/blade piercing ropes, providing triple protection against intrusion.

Q3: Applicable scenarios?

High security places such as military bases, prisons, and nuclear power plants; More resistant to climbing than peach shaped fences, but at a higher cost.

Q4: How long can it be used?

Galvanized+dip coated, salt spray test for over 1000 hours without rusting; PVDF coating for coastal environments, with a lifespan of 25 years.

Q5: Size and installation?

Customizable height of 1.5-4 meters, standard board width of 2-3 meters; Modular installation, daily installation of 200 meters, recommended bolt+welding fixation.

Q6: Color selection?

Standard colors such as dark green, gray white, etc. can be customized with camouflage or corporate colors; Use dark colors for concealed scenes and bright colors for identification scenes.

Q7: Maintenance costs?

Rinse with clean water, inspect the coating every six months, repair any damages, and have low long-term costs.

Q8: How to choose specifications?

Select a high-risk scenario with a height of 4 meters, 5mm thick wire, and double coating; Low risk selection of 2-3 meters+3-4mm wire+single coating requires professional evaluation.

As a benchmark product for high-security scenarios, the 358 anti-climb fence's technical specifications and performance advantages are fully demonstrated through the following structured analysis:

Core Parameters and Protection Principle

Naming Logic:

The high-density grid structure, constructed with 3-inch (76mm) horizontal reinforcement spacing, 0.5-inch (12mm) vertical reinforcement spacing, and No. 8 steel wire (4mm diameter), directly physically blocks intrusions such as climbing and cutting.

Anti-climb Mechanism:

The 76mm x 12mm precision grid effectively reduces finger grip space, while combined with 3-5mm shear-resistant steel wire, it provides dual physical protection.

The top can be integrated with a Y-shaped anti-climb bracket or accordion-type barbed wire to create a three-dimensional protective network.

The cold-drawn Q235 low-carbon steel wire (tensile strength ≥500MPa) undergoes a triple anti-corrosion treatment process of galvanizing, plastic dipping, and spray coating, resulting in over 1000 hours of rust-free salt spray testing. The PVDF fluorocarbon coating has a service life of up to 25 years in coastal high-salt spray environments.

Structural Performance and Customization Capabilities

Stability Design:

The rectangular steel tube frame strengthens the structural support and is secured with anchor bolts, capable of withstanding wind loads of magnitude 8 and impacts in earthquake zones of magnitude 8.

The modular installation system utilizes a dual bolting and welding process, enabling rapid assembly of individual panels, with a daily construction capacity of up to 200 meters. It is compatible with concrete foundations or quick-install brackets.

Dimensions and Customization:

Heights range from 1.5 to 4 meters (the super-high-rise 4-meter version is designed for airport and border isolation), with standard panel widths of 2 to 3 meters. Custom sizes are also supported.

The color palette includes standard colors such as dark green, grayish white, police blue, and desert yellow, with camouflage paint or corporate colors available to balance concealment and visual recognition.

Application Scenarios and Cost-Effectiveness

Suitable for High-Risk Scenarios:

Military locations (ammunition depots, command centers), judicial systems (prisons/detention centers), energy facilities (power plants/oil depots), transportation hubs (airport/station isolation zones), and high-end properties (villa complexes/industrial parks).

Compared to peach-shaped fences, 358 fences offer superior climb resistance, but are more expensive.

Specifications should be selected based on the risk level (e.g., 4 meters high with 5mm steel wire and double coating are recommended for high-risk scenarios, while 2-3 meters with 3-4mm steel wire and single coating are recommended for low-risk scenarios).

Maintenance and Lifespan:

Daily maintenance requires only water rinsing, and coating damage can be partially repaired, significantly extending service life.

Combined with an electronic fence alarm system, it provides dual security protection, both physical and technical.

Technical Parameters in Depth

Material Processing: Low-carbon steel wire is cold-drawn to achieve the optimal balance between strength and ductility. Laser cutting ensures grid precision (76mm x 12mm), minimal error, and excellent flatness.

Coating System: Utilizing a combined galvanizing, plastic dipping, and spraying process, with optional PVDF fluorocarbon coating, it adapts to the corrosion requirements of various environments.

Global Case Verification

Proven in over 3,000 major projects worldwide, from Alaska's arctic bases to Middle Eastern desert prisons, from Nordic data centers to Southeast Asian port facilities, our rigorous engineering standards ensure an impeccable security perimeter.

Summary

Choosing 358 anti-climb fencing means choosing a proven protection solution proven in high-security scenarios worldwide. With comprehensive customization options for size, color, and installation methods, it can precisely adapt to diverse scenarios, including military, judicial, energy, transportation, and high-end real estate, ensuring professional-grade security. For customized protection plans, we can optimize the specifications, configuration, and installation plan based on specific scenario risk assessments.

FAQS:

Q1: What is the meaning of the name?

Horizontal spacing of 3 inches (76mm), vertical spacing of 0.5 inches (12mm), and No. 8 steel wire (4mm) form a high-density anti climbing grid.

Q2: Anti climbing principle?

The fine mesh prevents grasping, the thick steel wire is resistant to cutting, and the top can be equipped with anti climbing/blade piercing ropes, providing triple protection against intrusion.

Q3: Applicable scenarios?

High security places such as military bases, prisons, and nuclear power plants; More resistant to climbing than peach shaped fences, but at a higher cost.

Q4: How long can it be used?

Galvanized+dip coated, salt spray test for over 1000 hours without rusting; PVDF coating for coastal environments, with a lifespan of 25 years.

Q5: Size and installation?

Customizable height of 1.5-4 meters, standard board width of 2-3 meters; Modular installation, daily installation of 200 meters, recommended bolt+welding fixation.

Q6: Color selection?

Standard colors such as dark green, gray white, etc. can be customized with camouflage or corporate colors; Use dark colors for concealed scenes and bright colors for identification scenes.

Q7: Maintenance costs?

Rinse with clean water, inspect the coating every six months, repair any damages, and have low long-term costs.

Q8: How to choose specifications?

Select a high-risk scenario with a height of 4 meters, 5mm thick wire, and double coating; Low risk selection of 2-3 meters+3-4mm wire+single coating requires professional evaluation.