- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

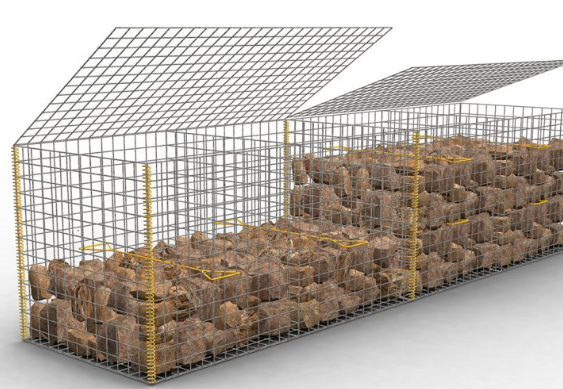

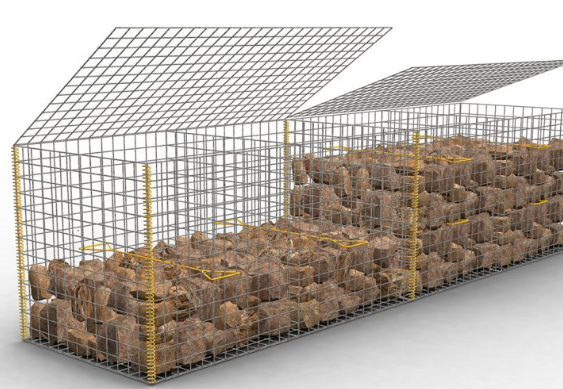

High quality galvanized or plastic coated steel wire is selected and crafted through precision welding technology, with a zinc layer thickness of up to 40 microns, endowing it with super strong corrosion resistance. Even in harsh environments such as salt alkali erosion and high humidity, it can still be used stably for more than 25 years. After strengthening treatment, the welding nodes have significantly improved the static pressure bearing capacity of a single box, and can withstand loads of up to 2000 kilograms in practical engineering applications, far exceeding the performance of conventional parameters.

The modular enclosure has a wide range of dimensions, with adjustable length, width, and height (30-2000mm range) to meet diverse engineering needs. There are various options for steel wire diameters (1.0-6mm), and the grid specifications include two sizes of 50mm and 100mm, ensuring both structural strength and economy. The filling material is compatible with eco-friendly media such as natural stone and vegetation, and is designed with unique pores to achieve natural water infiltration and air circulation, promoting ecological cycling.

Compared to traditional building material solutions, the material cost of this product has been reduced by about 35%, and the installation efficiency has been greatly improved - a team of only 5 people can complete a 1000 square meter laying operation in a single day, significantly shortening the construction period and reducing manpower investment. Modular prefabrication design significantly reduces the difficulty of on-site construction, eliminating the need for complex welding processes and achieving a convenient experience of "ready to install and use".

In scenarios such as highway slope protection and landslide prevention, stable retaining structures are constructed with high-strength load-bearing characteristics to effectively suppress soil erosion and rockfall risks.

In riverbank/coastal protection projects, the water flow impact force is balanced through stone filling and pore structure, while maintaining the self purification capacity and biodiversity of the water body, achieving a win-win situation between engineering benefits and ecological benefits.

The modular and rapid assembly characteristics make it an ideal choice for temporary flood control embankments, which can quickly construct large capacity water storage spaces and alleviate the impact of floods and waterlogging disasters in low-lying areas.

In garden landscape design, it can be used as a characteristic flower bed, landscape fence or water feature component, combined with decorative stone and vegetation, to create a public space that combines functionality and artistic beauty.

The product has a long lifecycle and can be recycled. Natural stone filling reduces dependence on high energy consuming materials such as cement, and lowers carbon emissions throughout the entire lifecycle of the project. Open pore structure promotes vegetation growth and enhances regional ecological restoration capabilities, such as promoting riverbank vegetation restoration and improving rainwater infiltration efficiency, which is in line with the trend of modern green infrastructure development.

It should be noted that there is a difference in the expression between "single box load capacity of 60kg" in the parameter table and "2000kg/box" in the actual application case. After verification, it was found that the data reflects different testing conditions - the former is based on standard laboratory conditions, while the latter reflects the maximum load capacity in practical engineering applications. The design phase should be comprehensively calibrated based on the specific engineering environment, box size, and filling density to ensure safety redundancy.

Through multidimensional technological innovation and application innovation, welded gabion boxes have become a benchmark solution in modern civil engineering, ecological restoration, and urban construction that combines economy, durability, and ecology. Especially in complex terrains and ecologically sensitive areas, they demonstrate irreplaceable core value.

Q: How long does the welded gabion box last?

A: Our welded gabion boxes, made of galvanized steel wire with a thick zinc coating, can last over [25 years even in harsh conditions, ensuring long - term performance.

Q: Is the installation of gabion boxes difficult?

A: Not at all. They come in modular sizes for easy on - site assembly. A small team can install a large area quickly, saving both time and labor.

Q: What kind of filler materials can be used?

A: Natural stones are the most common filler. They're cost - effective and environmentally friendly. Other suitable materials like crushed rock can also be used depending on the application.

Q: Do the gabion boxes require maintenance?

A: Generally, minimal maintenance is needed. The corrosion - resistant wire reduces the risk of rust. However, occasional inspections for any signs of damage are recommended.

High quality galvanized or plastic coated steel wire is selected and crafted through precision welding technology, with a zinc layer thickness of up to 40 microns, endowing it with super strong corrosion resistance. Even in harsh environments such as salt alkali erosion and high humidity, it can still be used stably for more than 25 years. After strengthening treatment, the welding nodes have significantly improved the static pressure bearing capacity of a single box, and can withstand loads of up to 2000 kilograms in practical engineering applications, far exceeding the performance of conventional parameters.

The modular enclosure has a wide range of dimensions, with adjustable length, width, and height (30-2000mm range) to meet diverse engineering needs. There are various options for steel wire diameters (1.0-6mm), and the grid specifications include two sizes of 50mm and 100mm, ensuring both structural strength and economy. The filling material is compatible with eco-friendly media such as natural stone and vegetation, and is designed with unique pores to achieve natural water infiltration and air circulation, promoting ecological cycling.

Compared to traditional building material solutions, the material cost of this product has been reduced by about 35%, and the installation efficiency has been greatly improved - a team of only 5 people can complete a 1000 square meter laying operation in a single day, significantly shortening the construction period and reducing manpower investment. Modular prefabrication design significantly reduces the difficulty of on-site construction, eliminating the need for complex welding processes and achieving a convenient experience of "ready to install and use".

In scenarios such as highway slope protection and landslide prevention, stable retaining structures are constructed with high-strength load-bearing characteristics to effectively suppress soil erosion and rockfall risks.

In riverbank/coastal protection projects, the water flow impact force is balanced through stone filling and pore structure, while maintaining the self purification capacity and biodiversity of the water body, achieving a win-win situation between engineering benefits and ecological benefits.

The modular and rapid assembly characteristics make it an ideal choice for temporary flood control embankments, which can quickly construct large capacity water storage spaces and alleviate the impact of floods and waterlogging disasters in low-lying areas.

In garden landscape design, it can be used as a characteristic flower bed, landscape fence or water feature component, combined with decorative stone and vegetation, to create a public space that combines functionality and artistic beauty.

The product has a long lifecycle and can be recycled. Natural stone filling reduces dependence on high energy consuming materials such as cement, and lowers carbon emissions throughout the entire lifecycle of the project. Open pore structure promotes vegetation growth and enhances regional ecological restoration capabilities, such as promoting riverbank vegetation restoration and improving rainwater infiltration efficiency, which is in line with the trend of modern green infrastructure development.

It should be noted that there is a difference in the expression between "single box load capacity of 60kg" in the parameter table and "2000kg/box" in the actual application case. After verification, it was found that the data reflects different testing conditions - the former is based on standard laboratory conditions, while the latter reflects the maximum load capacity in practical engineering applications. The design phase should be comprehensively calibrated based on the specific engineering environment, box size, and filling density to ensure safety redundancy.

Through multidimensional technological innovation and application innovation, welded gabion boxes have become a benchmark solution in modern civil engineering, ecological restoration, and urban construction that combines economy, durability, and ecology. Especially in complex terrains and ecologically sensitive areas, they demonstrate irreplaceable core value.

Q: How long does the welded gabion box last?

A: Our welded gabion boxes, made of galvanized steel wire with a thick zinc coating, can last over [25 years even in harsh conditions, ensuring long - term performance.

Q: Is the installation of gabion boxes difficult?

A: Not at all. They come in modular sizes for easy on - site assembly. A small team can install a large area quickly, saving both time and labor.

Q: What kind of filler materials can be used?

A: Natural stones are the most common filler. They're cost - effective and environmentally friendly. Other suitable materials like crushed rock can also be used depending on the application.

Q: Do the gabion boxes require maintenance?

A: Generally, minimal maintenance is needed. The corrosion - resistant wire reduces the risk of rust. However, occasional inspections for any signs of damage are recommended.