- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

Long term protection system: using high zinc coated galvanized steel wire as the substrate, with a coating thickness of 245g/m ², supplemented by PVC composite coating or 304/316 stainless steel material upgrade plan. Through accelerated aging testing in the laboratory, it has been verified that the structural integrity can still be maintained for more than 50 years in extreme environments such as salt spray and acid rain, and its anti-corrosion performance surpasses traditional protective materials, forming a dual anti-corrosion barrier.

Intelligent stress dispersion structure: The original double stranded hexagonal grid achieves three-dimensional stress balanced transmission, with a measured compressive strength of 500kN/m ² and no plastic deformation. The modules are connected by toothed interlocking, forming a self stabilizing system under dynamic loads such as earthquakes and flood peaks. It is particularly suitable for large retaining walls and high steep slope projects, and its stability has been verified through laboratory impact testing.

Ecological Permeable Network: With a grid porosity of over 35%, dynamic hydraulic channels are constructed to effectively reduce static water pressure by over 90%, while simultaneously addressing soil erosion and local waterlogging issues. The open structure allows plant roots to naturally penetrate, forming an engineering ecological composite protective layer, promoting slope ecological restoration, and achieving bioengineered composite protection.

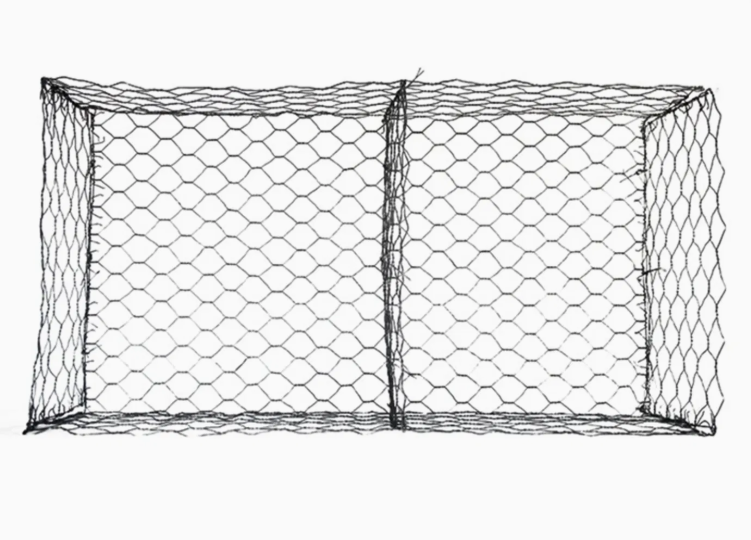

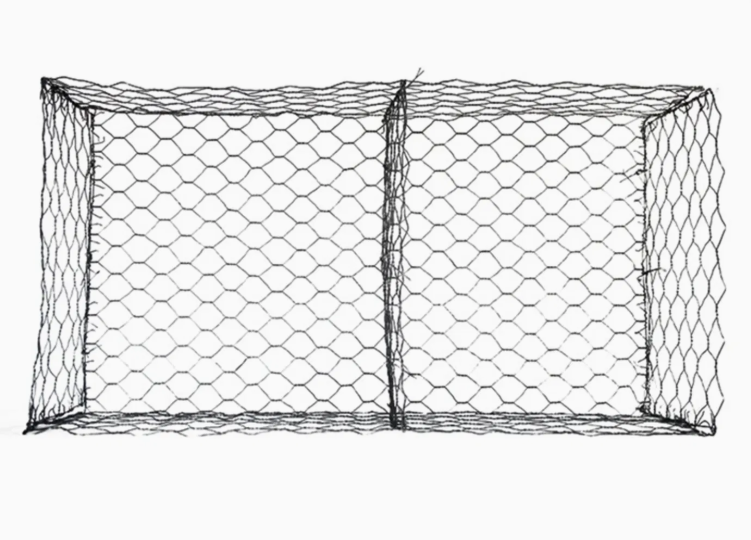

Modular rapid construction: Standard unit sizes range from 1m x 1m x 1m to 3m x 1m x 0.5m series, supporting terrain adaptive splicing. The patented buckle design enables tool free rapid assembly, with a daily installation capacity of up to 50 cubic meters for two people, which is three times more efficient than traditional masonry processes, reducing overall costs by 40%, and saving 70% of construction time and 40% of labor costs.

The steel wire specification adopts a combination of main wire 2.0-4.0mm and binding wire 2.0-2.5mm to achieve a golden ratio of strength and flexibility. The grid size range is from 60 × 80mm to 100 × 120mm, suitable for filling materials of different particle sizes, such as natural crushed stone or recycled aggregates. The module size can be customized, ranging from 1m x 1m x 1m to 3m x 1m x 0.5m, accurately adapting to complex terrain and landforms. The anti-corrosion grade meets the ASTM B695 C4-C5 standard and is suitable for harsh environments such as marine and chemical industries. In terms of permeability performance, the dynamic permeability coefficient shall not be less than 3 × 10 ⁻ cm/s, meeting the requirements of water conservancy engineering permeability specifications.

Ecological riverbank management: In dynamic water flow areas, grid structures protect riverbanks through energy dissipation and erosion reduction, combined with vegetation restoration to form ecological riverbanks. For example, in the protection project of a tributary of the Yangtze River, this plan reduces shoreline erosion by 85% and establishes fish spawning grounds to promote ecological restoration.

Gravity retaining system: Modular stacking forms a self stabilizing structure without the need for concrete foundations, suitable for slope protection of mountainous roads, reducing costs by 35% while providing strong support capabilities.

Urban landscape revolution: Transparent grid design achieves visual transparency, and nighttime light mapping creates unique light and shadow effects. The integrated solar lighting system on the landscape wall of Shanghai Binjiang Trail has become a new landmark of urban landscape.

Mountain disaster prevention and control: The grid and vegetation composite system achieves ecological soil stabilization of slopes. In the debris flow protection project in southwestern mountainous areas, a reinforced grid structure is adopted, which increases the impact resistance by 200% and effectively prevents mountain disasters.

Intelligent monitoring module: Built in sensors monitor stress and displacement in real-time, and data is synchronized to the cloud warning system for remote monitoring and warning.

Ecological enhancement technology: Developing biodegradable biological fillers to achieve ecological cycling throughout the entire life cycle of engineering and promote sustainable development.

Customized production: 3D modeling software supports automatic generation of optimal module layout schemes for complex terrains, improving design efficiency and construction accuracy.

This product demonstrates comprehensive advantages that traditional materials cannot match in fields such as water conservancy engineering, municipal construction, and landscape design through triple innovation in materials science, structural engineering, and ecological technology. It has become a benchmark solution for green infrastructure construction and promotes the intelligent development of engineering protection and ecological integration.

Q1: How long can the gabion box last?

A: Made of corrosion - resistant materials like galvanized steel, it can last over 50 years in normal conditions. The zinc coating and wire quality ensure long - term durability.

Q2: Is the installation of gabion boxes difficult?

A: Not at all. Their modular design allows for easy assembly. A regular team can quickly install them. Installation instructions are provided, and no special skills are required.

Q3: Can the gabion box withstand heavy floods?

A: Definitely. With its stable structure and high - strength wire mesh, it can endure the strong impact of floods. Tests show it can resist high - speed water flow, protecting riverbanks effectively.

Q4: What kind of filling materials are suitable?

A: Stones are the most common. They should be of appropriate size, usually 8 - 16 cm. Gravel and broken concrete can also be used, as long as they can fill the box tightly for better stability.

Long term protection system: using high zinc coated galvanized steel wire as the substrate, with a coating thickness of 245g/m ², supplemented by PVC composite coating or 304/316 stainless steel material upgrade plan. Through accelerated aging testing in the laboratory, it has been verified that the structural integrity can still be maintained for more than 50 years in extreme environments such as salt spray and acid rain, and its anti-corrosion performance surpasses traditional protective materials, forming a dual anti-corrosion barrier.

Intelligent stress dispersion structure: The original double stranded hexagonal grid achieves three-dimensional stress balanced transmission, with a measured compressive strength of 500kN/m ² and no plastic deformation. The modules are connected by toothed interlocking, forming a self stabilizing system under dynamic loads such as earthquakes and flood peaks. It is particularly suitable for large retaining walls and high steep slope projects, and its stability has been verified through laboratory impact testing.

Ecological Permeable Network: With a grid porosity of over 35%, dynamic hydraulic channels are constructed to effectively reduce static water pressure by over 90%, while simultaneously addressing soil erosion and local waterlogging issues. The open structure allows plant roots to naturally penetrate, forming an engineering ecological composite protective layer, promoting slope ecological restoration, and achieving bioengineered composite protection.

Modular rapid construction: Standard unit sizes range from 1m x 1m x 1m to 3m x 1m x 0.5m series, supporting terrain adaptive splicing. The patented buckle design enables tool free rapid assembly, with a daily installation capacity of up to 50 cubic meters for two people, which is three times more efficient than traditional masonry processes, reducing overall costs by 40%, and saving 70% of construction time and 40% of labor costs.

The steel wire specification adopts a combination of main wire 2.0-4.0mm and binding wire 2.0-2.5mm to achieve a golden ratio of strength and flexibility. The grid size range is from 60 × 80mm to 100 × 120mm, suitable for filling materials of different particle sizes, such as natural crushed stone or recycled aggregates. The module size can be customized, ranging from 1m x 1m x 1m to 3m x 1m x 0.5m, accurately adapting to complex terrain and landforms. The anti-corrosion grade meets the ASTM B695 C4-C5 standard and is suitable for harsh environments such as marine and chemical industries. In terms of permeability performance, the dynamic permeability coefficient shall not be less than 3 × 10 ⁻ cm/s, meeting the requirements of water conservancy engineering permeability specifications.

Ecological riverbank management: In dynamic water flow areas, grid structures protect riverbanks through energy dissipation and erosion reduction, combined with vegetation restoration to form ecological riverbanks. For example, in the protection project of a tributary of the Yangtze River, this plan reduces shoreline erosion by 85% and establishes fish spawning grounds to promote ecological restoration.

Gravity retaining system: Modular stacking forms a self stabilizing structure without the need for concrete foundations, suitable for slope protection of mountainous roads, reducing costs by 35% while providing strong support capabilities.

Urban landscape revolution: Transparent grid design achieves visual transparency, and nighttime light mapping creates unique light and shadow effects. The integrated solar lighting system on the landscape wall of Shanghai Binjiang Trail has become a new landmark of urban landscape.

Mountain disaster prevention and control: The grid and vegetation composite system achieves ecological soil stabilization of slopes. In the debris flow protection project in southwestern mountainous areas, a reinforced grid structure is adopted, which increases the impact resistance by 200% and effectively prevents mountain disasters.

Intelligent monitoring module: Built in sensors monitor stress and displacement in real-time, and data is synchronized to the cloud warning system for remote monitoring and warning.

Ecological enhancement technology: Developing biodegradable biological fillers to achieve ecological cycling throughout the entire life cycle of engineering and promote sustainable development.

Customized production: 3D modeling software supports automatic generation of optimal module layout schemes for complex terrains, improving design efficiency and construction accuracy.

This product demonstrates comprehensive advantages that traditional materials cannot match in fields such as water conservancy engineering, municipal construction, and landscape design through triple innovation in materials science, structural engineering, and ecological technology. It has become a benchmark solution for green infrastructure construction and promotes the intelligent development of engineering protection and ecological integration.

Q1: How long can the gabion box last?

A: Made of corrosion - resistant materials like galvanized steel, it can last over 50 years in normal conditions. The zinc coating and wire quality ensure long - term durability.

Q2: Is the installation of gabion boxes difficult?

A: Not at all. Their modular design allows for easy assembly. A regular team can quickly install them. Installation instructions are provided, and no special skills are required.

Q3: Can the gabion box withstand heavy floods?

A: Definitely. With its stable structure and high - strength wire mesh, it can endure the strong impact of floods. Tests show it can resist high - speed water flow, protecting riverbanks effectively.

Q4: What kind of filling materials are suitable?

A: Stones are the most common. They should be of appropriate size, usually 8 - 16 cm. Gravel and broken concrete can also be used, as long as they can fill the box tightly for better stability.