- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The welded mesh cage is formed by welding galvanized/plastic coated steel wires to form a rectangular mesh cage structure. Its technical characteristics and engineering value are reflected in:

Long term anti-corrosion system: The 40 μ m zinc coating achieves a corrosion resistance life of over 25 years, suitable for harsh scenarios such as riverbank erosion and industrial corrosion, and its anti-corrosion performance surpasses traditional stone masonry structures.

Structural strength optimization: Welding nodes ensure that a single box can withstand static pressure of 1000kg without deformation. In the application of retaining walls, a single module can achieve a bearing capacity of 2000kg (to be verified according to engineering specifications). The parameter table for 60kg/box is the standard test value, and the actual evaluation needs to be based on the module size.

Prefabricated efficiency revolution: Modular size (adjustable from 20-2000mm in length, width, and height, with a volume of 0.3-8m ³) supports a daily installation of 1000 square meters for a team of 5 people, shortening the construction period by 70%, reducing material costs by 25% -35%, and reducing overall costs by 40% compared to traditional solutions.

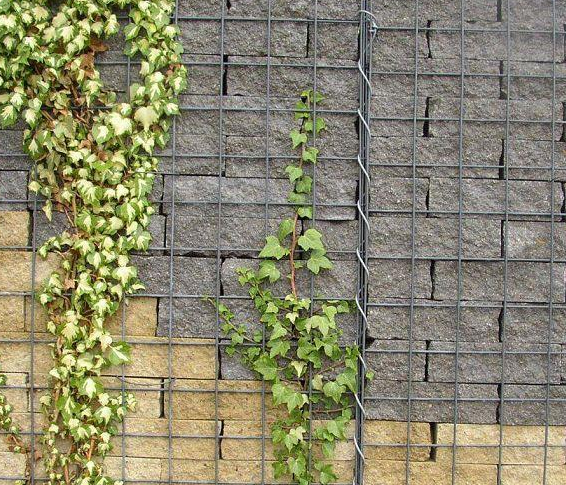

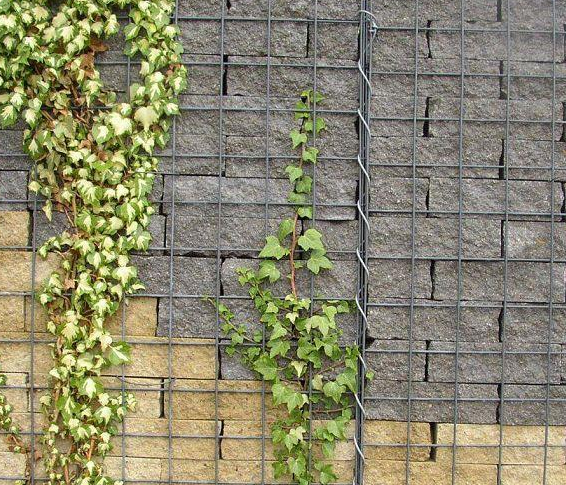

Ecological collaborative design: 50mm/100mm mesh ensures a porosity of over 35%, forming a water air circulation channel. Natural stone filling promotes the penetration of vegetation roots, achieving a dual function of "engineering protection ecological restoration".

Full scenario applicability: covering multiple scenarios such as road retaining walls, anti-skid slopes, riverbank erosion resistance, rapid deployment of flood control, urban landscape design, and water conservancy engineering, municipal protection, and landscape engineering.

Full cycle economy: Zinc coating anti-corrosion reduces the need for corrosion maintenance, requiring only regular inspections, and the maintenance cost throughout the lifecycle is significantly lower than traditional solutions such as concrete.

This product integrates material innovation, structural optimization, and ecological technology to build collaborative advantages in the dimensions of "protection ecology economy", becoming a technological benchmark in the global green infrastructure field. Attention should be paid to the load difference between the parameter table and the application case. In actual engineering, module specifications and testing standards need to be verified according to the specifications.

FAQs:

Q: How long does the welded gabion box last?

A: Our welded gabion boxes, made of galvanized steel wire with a thick zinc coating, can last over [25 years even in harsh conditions, ensuring long - term performance.

Q: Is the installation of gabion boxes difficult?

A: Not at all. They come in modular sizes for easy on - site assembly. A small team can install a large area quickly, saving both time and labor.

Q: What kind of filler materials can be used?

A: Natural stones are the most common filler. They're cost - effective and environmentally friendly. Other suitable materials like crushed rock can also be used depending on the application.

Q: Do the gabion boxes require maintenance?

A: Generally, minimal maintenance is needed. The corrosion - resistant wire reduces the risk of rust. However, occasional inspections for any signs of damage are recommended.

The welded mesh cage is formed by welding galvanized/plastic coated steel wires to form a rectangular mesh cage structure. Its technical characteristics and engineering value are reflected in:

Long term anti-corrosion system: The 40 μ m zinc coating achieves a corrosion resistance life of over 25 years, suitable for harsh scenarios such as riverbank erosion and industrial corrosion, and its anti-corrosion performance surpasses traditional stone masonry structures.

Structural strength optimization: Welding nodes ensure that a single box can withstand static pressure of 1000kg without deformation. In the application of retaining walls, a single module can achieve a bearing capacity of 2000kg (to be verified according to engineering specifications). The parameter table for 60kg/box is the standard test value, and the actual evaluation needs to be based on the module size.

Prefabricated efficiency revolution: Modular size (adjustable from 20-2000mm in length, width, and height, with a volume of 0.3-8m ³) supports a daily installation of 1000 square meters for a team of 5 people, shortening the construction period by 70%, reducing material costs by 25% -35%, and reducing overall costs by 40% compared to traditional solutions.

Ecological collaborative design: 50mm/100mm mesh ensures a porosity of over 35%, forming a water air circulation channel. Natural stone filling promotes the penetration of vegetation roots, achieving a dual function of "engineering protection ecological restoration".

Full scenario applicability: covering multiple scenarios such as road retaining walls, anti-skid slopes, riverbank erosion resistance, rapid deployment of flood control, urban landscape design, and water conservancy engineering, municipal protection, and landscape engineering.

Full cycle economy: Zinc coating anti-corrosion reduces the need for corrosion maintenance, requiring only regular inspections, and the maintenance cost throughout the lifecycle is significantly lower than traditional solutions such as concrete.

This product integrates material innovation, structural optimization, and ecological technology to build collaborative advantages in the dimensions of "protection ecology economy", becoming a technological benchmark in the global green infrastructure field. Attention should be paid to the load difference between the parameter table and the application case. In actual engineering, module specifications and testing standards need to be verified according to the specifications.

FAQs:

Q: How long does the welded gabion box last?

A: Our welded gabion boxes, made of galvanized steel wire with a thick zinc coating, can last over [25 years even in harsh conditions, ensuring long - term performance.

Q: Is the installation of gabion boxes difficult?

A: Not at all. They come in modular sizes for easy on - site assembly. A small team can install a large area quickly, saving both time and labor.

Q: What kind of filler materials can be used?

A: Natural stones are the most common filler. They're cost - effective and environmentally friendly. Other suitable materials like crushed rock can also be used depending on the application.

Q: Do the gabion boxes require maintenance?

A: Generally, minimal maintenance is needed. The corrosion - resistant wire reduces the risk of rust. However, occasional inspections for any signs of damage are recommended.