- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

Vanguard Defense Barrier: Global Threat Defense Expert

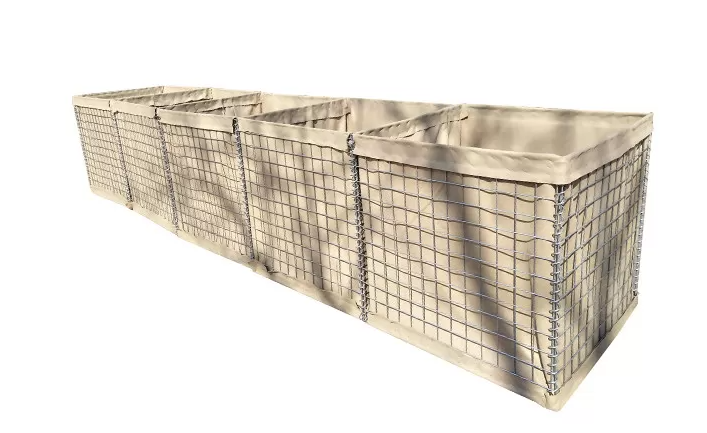

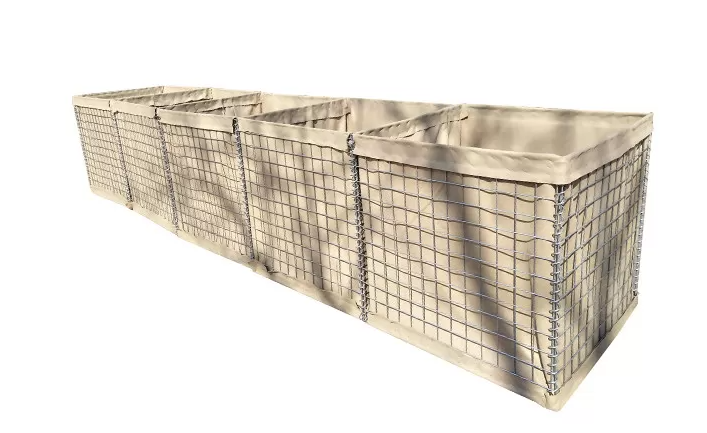

This product is built to military grade standards and uses 4-5 mm high-strength galvanized/zinc aluminum alloy steel wire as the core skeleton. It integrates an intelligent modular structure of welded gabion and non-woven geotextile to construct a three-dimensional protective network that can be quickly customized. Its unique "light wave protection belt" technology achieves triple defense of live ammunition, energy weapons, and explosive shock waves, verifying the excellent performance of all-round security barriers in the actual combat of the "Artemis" military fortress.

Core Feature Refactoring

Ultra durable material: maintains structural integrity through shrapnel impact testing, with anti-corrosion performance lasting for 25 years in saline alkali high humidity environments, reducing maintenance costs by 40%, and a tensile strength of up to 1500MPa.

Intelligent modularization: Unit components support free splicing, and can be quickly built from 5-meter micro outposts to 5-kilometer level strategic defense lines, adapting to cross scenario needs such as military bases, shooting ranges, peace mission areas, civilian flood control, and hazardous chemical protection.

Rapid deployment: Using excavators/loaders in conjunction with local sand and gravel/loess filling, the installation efficiency is increased by 300% compared to traditional sandbags, achieving a "ready to use" rapid response capability.

Eco friendly: 85% recyclable materials, natural fillers reduce cement dependence, and carbon emissions throughout the entire lifecycle are reduced by 35%, in line with the concept of green protection.

Technical Parameters Essentials

Steel wire specification: 4-5mm galvanized/zinc aluminum alloy, certified with A-level blast resistance

Protection level: able to withstand 120mm mortar shrapnel impact and energy weapon attacks

Assembly efficiency: A standard unit team of 5 people can complete 50 meter construction in 1.5 hours

Environmental features: Supports local material filling, reduces transportation energy consumption

Deepening application scenarios

In the military field, a "hard shell soft foundation" composite protective layer is constructed for ammunition depots to resist drone bombing and long-range firepower strikes; Civilian scenario: Forming gradient pore structures in flood prone areas, which not only block water but also allow permeability, and achieving dual effects of ecological flood control with vegetation restoration; Industrial safety: Build triple safety buffer zones around hazardous chemical warehouses to prevent leakage, spread, and secondary explosions. This product has achieved triple breakthroughs in material innovation, structural optimization, and intelligent defense technology, redefining modern protection standards and becoming a strategic choice for national defense construction and people's livelihood security.

Q1: How strong is the Defensive Barrier?

A1: Made of high - strength galvanized or zinc - aluminum alloy wires, it can withstand shell fragments in military scenarios and block floodwaters in civilian ones, offering reliable protection.

Q2: Is the installation process complicated?

A2: Not at all. With the help of machinery like excavators, and using local filling materials, installation is fast. It's much quicker than traditional sandbag - based defenses.

Q3: Can it be used in various terrains?

A3: Absolutely. Its modular design allows for easy adaptation to different terrains, whether it's flat ground at a military base or uneven surfaces around a flood - prone area.

Q4: How does it protect in dangerous goods warehouses?

A4: It stops unauthorized entry and contains potential leaks or blasts. The robust materials and design ensure the safety of the surrounding area and prevent disasters.

Vanguard Defense Barrier: Global Threat Defense Expert

This product is built to military grade standards and uses 4-5 mm high-strength galvanized/zinc aluminum alloy steel wire as the core skeleton. It integrates an intelligent modular structure of welded gabion and non-woven geotextile to construct a three-dimensional protective network that can be quickly customized. Its unique "light wave protection belt" technology achieves triple defense of live ammunition, energy weapons, and explosive shock waves, verifying the excellent performance of all-round security barriers in the actual combat of the "Artemis" military fortress.

Core Feature Refactoring

Ultra durable material: maintains structural integrity through shrapnel impact testing, with anti-corrosion performance lasting for 25 years in saline alkali high humidity environments, reducing maintenance costs by 40%, and a tensile strength of up to 1500MPa.

Intelligent modularization: Unit components support free splicing, and can be quickly built from 5-meter micro outposts to 5-kilometer level strategic defense lines, adapting to cross scenario needs such as military bases, shooting ranges, peace mission areas, civilian flood control, and hazardous chemical protection.

Rapid deployment: Using excavators/loaders in conjunction with local sand and gravel/loess filling, the installation efficiency is increased by 300% compared to traditional sandbags, achieving a "ready to use" rapid response capability.

Eco friendly: 85% recyclable materials, natural fillers reduce cement dependence, and carbon emissions throughout the entire lifecycle are reduced by 35%, in line with the concept of green protection.

Technical Parameters Essentials

Steel wire specification: 4-5mm galvanized/zinc aluminum alloy, certified with A-level blast resistance

Protection level: able to withstand 120mm mortar shrapnel impact and energy weapon attacks

Assembly efficiency: A standard unit team of 5 people can complete 50 meter construction in 1.5 hours

Environmental features: Supports local material filling, reduces transportation energy consumption

Deepening application scenarios

In the military field, a "hard shell soft foundation" composite protective layer is constructed for ammunition depots to resist drone bombing and long-range firepower strikes; Civilian scenario: Forming gradient pore structures in flood prone areas, which not only block water but also allow permeability, and achieving dual effects of ecological flood control with vegetation restoration; Industrial safety: Build triple safety buffer zones around hazardous chemical warehouses to prevent leakage, spread, and secondary explosions. This product has achieved triple breakthroughs in material innovation, structural optimization, and intelligent defense technology, redefining modern protection standards and becoming a strategic choice for national defense construction and people's livelihood security.

Q1: How strong is the Defensive Barrier?

A1: Made of high - strength galvanized or zinc - aluminum alloy wires, it can withstand shell fragments in military scenarios and block floodwaters in civilian ones, offering reliable protection.

Q2: Is the installation process complicated?

A2: Not at all. With the help of machinery like excavators, and using local filling materials, installation is fast. It's much quicker than traditional sandbag - based defenses.

Q3: Can it be used in various terrains?

A3: Absolutely. Its modular design allows for easy adaptation to different terrains, whether it's flat ground at a military base or uneven surfaces around a flood - prone area.

Q4: How does it protect in dangerous goods warehouses?

A4: It stops unauthorized entry and contains potential leaks or blasts. The robust materials and design ensure the safety of the surrounding area and prevent disasters.