- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

JunHe

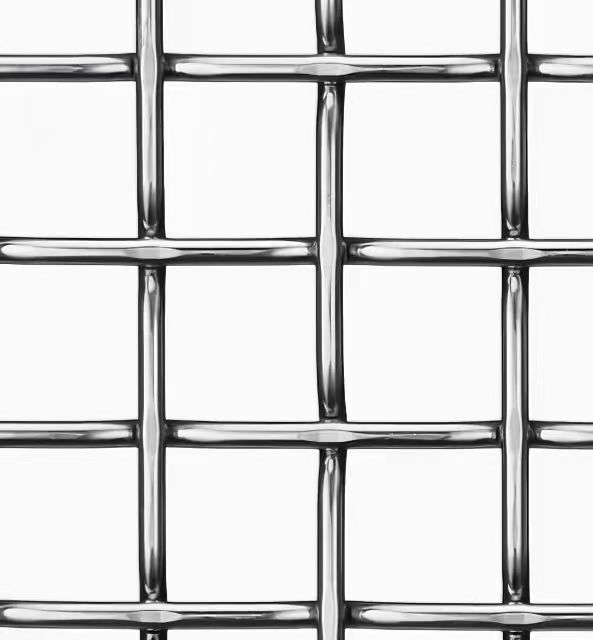

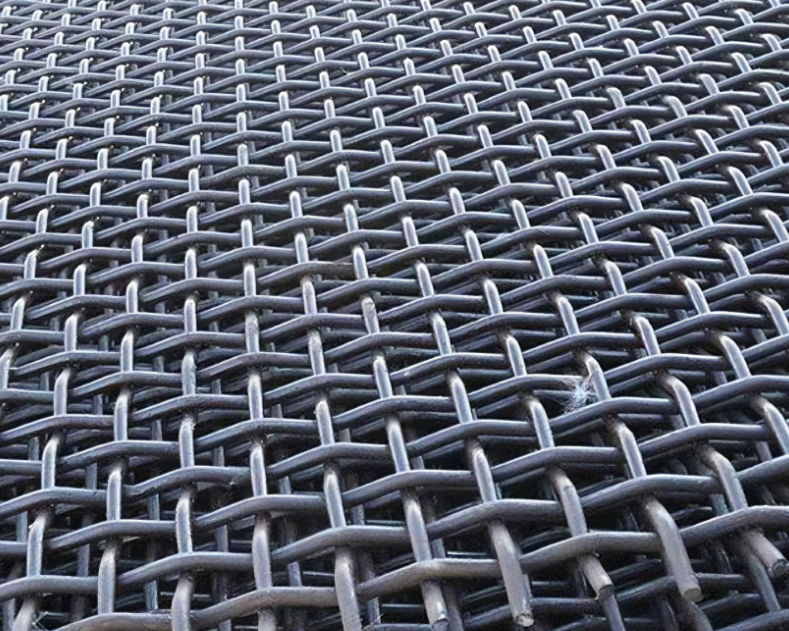

it's 3 - 5 times more wear - resistant than regular steel meshes

After 1000 - hour salt - spray tests, it shows no rust, outperforming many metal meshes and extending

It's applicable across mining, construction, and food processing.

We provide custom - made meshes, tailoring to specific mesh sizes, shapes, or extra features. This meets diverse customer needs.

Available in a wide range, from 0.1mm aperture for fine screening to 50mm for coarse separation.

Composed mainly of high - grade manganese steel, with manganese content typically ranging from 11% - 14%.

Exhibits a high tensile strength of 800 - 1200 MPa.

In standardized impact tests, it can withstand impacts of up to 20 J without deformation.

After 1000 - hour salt - spray tests, it shows no signs of rust or degradation.

Rated as highly corrosion-resistant, it shows no rust or degradation after a 1000-hour salt spray test. This characteristic is critical for use in humid or corrosive environments, such as coastal construction sites and chemical processing plants.

Recycling facilities rely on the mesh to separate metals, plastics, and glass by size, significantly improving recycling efficiency.

Q1: What makes manganese steel suitable for screen meshes?

A1: Manganese steel has high wear - resistance and toughness. Its alloy composition, with 11% - 14% manganese, enables it to endure harsh conditions, making it ideal for screen meshes in various industries.

Q2: How long does the manganese steel screen mesh typically last?

A2: It depends on usage. In mining, with heavy - duty use, it can last 6 - 12 months. In less - demanding applications like food processing, it may last 1 - 2 years due to its durability.

Q3: Can the mesh be cleaned easily?

A3: Yes. For most applications, a simple water rinse or gentle brushing can remove debris. In cases of stubborn dirt, mild detergents can be used without affecting the mesh's integrity.

Q4: Is it possible to customize the mesh size?

A4: Absolutely. We offer a wide range of custom - made mesh sizes, from very fine to coarse, to meet specific industry needs. Just let us know your requirements.

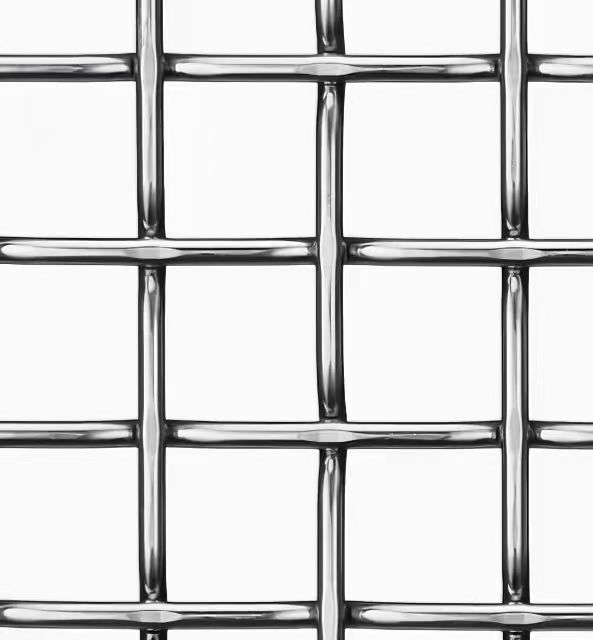

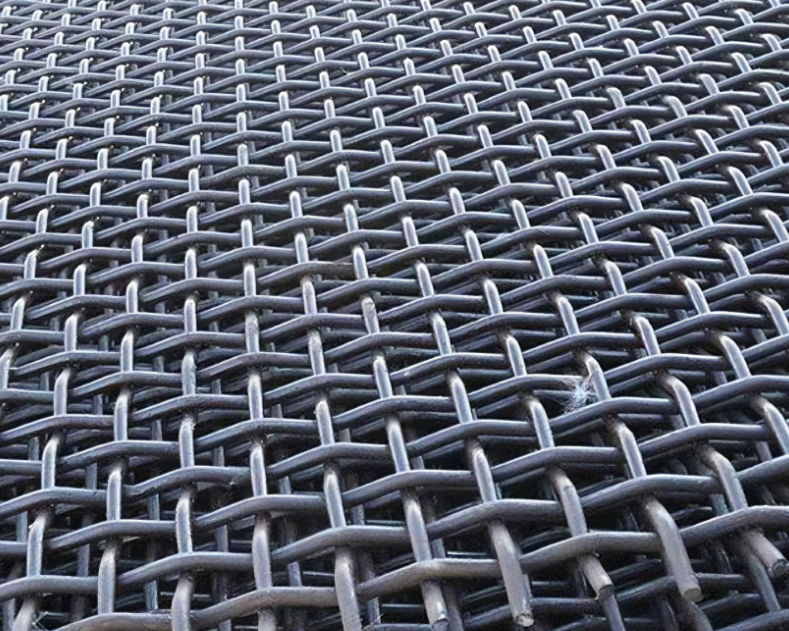

it's 3 - 5 times more wear - resistant than regular steel meshes

After 1000 - hour salt - spray tests, it shows no rust, outperforming many metal meshes and extending

It's applicable across mining, construction, and food processing.

We provide custom - made meshes, tailoring to specific mesh sizes, shapes, or extra features. This meets diverse customer needs.

Available in a wide range, from 0.1mm aperture for fine screening to 50mm for coarse separation.

Composed mainly of high - grade manganese steel, with manganese content typically ranging from 11% - 14%.

Exhibits a high tensile strength of 800 - 1200 MPa.

In standardized impact tests, it can withstand impacts of up to 20 J without deformation.

After 1000 - hour salt - spray tests, it shows no signs of rust or degradation.

Rated as highly corrosion-resistant, it shows no rust or degradation after a 1000-hour salt spray test. This characteristic is critical for use in humid or corrosive environments, such as coastal construction sites and chemical processing plants.

Recycling facilities rely on the mesh to separate metals, plastics, and glass by size, significantly improving recycling efficiency.

Q1: What makes manganese steel suitable for screen meshes?

A1: Manganese steel has high wear - resistance and toughness. Its alloy composition, with 11% - 14% manganese, enables it to endure harsh conditions, making it ideal for screen meshes in various industries.

Q2: How long does the manganese steel screen mesh typically last?

A2: It depends on usage. In mining, with heavy - duty use, it can last 6 - 12 months. In less - demanding applications like food processing, it may last 1 - 2 years due to its durability.

Q3: Can the mesh be cleaned easily?

A3: Yes. For most applications, a simple water rinse or gentle brushing can remove debris. In cases of stubborn dirt, mild detergents can be used without affecting the mesh's integrity.

Q4: Is it possible to customize the mesh size?

A4: Absolutely. We offer a wide range of custom - made mesh sizes, from very fine to coarse, to meet specific industry needs. Just let us know your requirements.