- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

JunHe

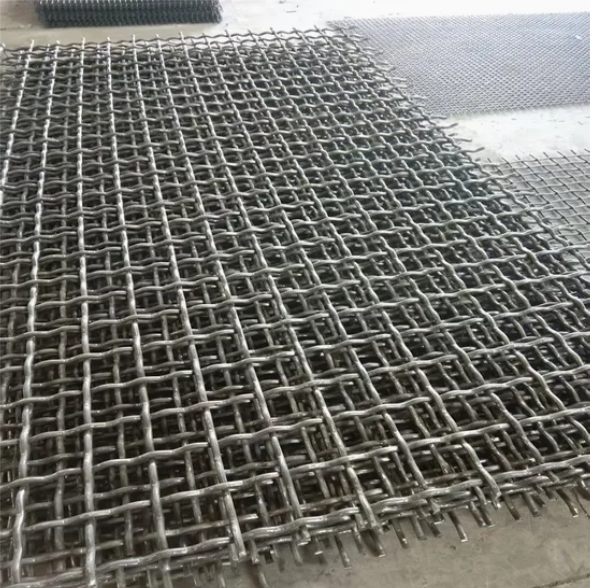

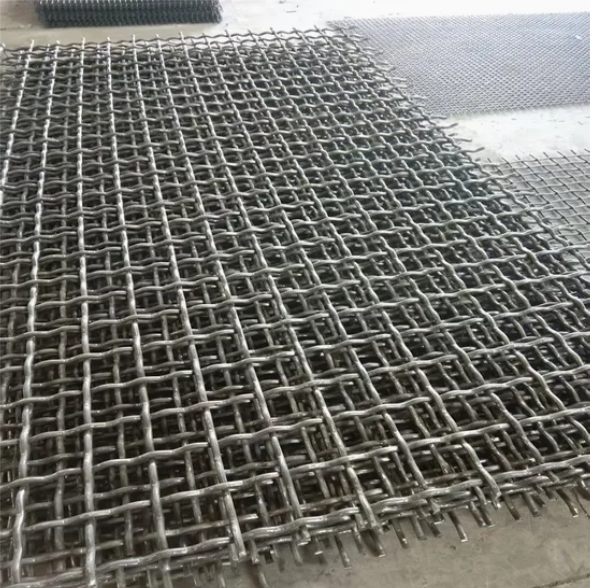

Manganese steel screen mesh is a robust and enduring product, crafted from premium-quality manganese steel. Its remarkable wear resistance makes it an ideal choice for harsh operating conditions.

This mesh is extensively utilized in mining, construction, and industrial screening operations to effectively separate materials based on size. Its sturdy construction enables it to bear heavy loads and withstand continuous vibration. With a variety of mesh sizes available, it can cater to different screening requirements, making it a reliable option for industries in search of durable and high-performance screening solutions.

Due to its unique alloy composition, manganese steel screen mesh exhibits outstanding durability. Tests have shown that it is 3 - 5 times more wear-resistant than ordinary steel meshes, making it particularly well-suited for mining and other industries that involve high levels of friction.

With precise mesh sizing, this screen mesh enables highly efficient screening. For instance, in sand screening processes, it can achieve a separation accuracy of up to 95%, thereby saving time and boosting productivity.

This mesh demonstrates excellent resistance to corrosion. After undergoing 1000-hour salt-spray tests, it remains free of rust, outperforming many other metal meshes and significantly extending its service life in various industrial environments.

It finds applications across a range of sectors, including mining, construction, and food processing. In the mining industry, it is used to separate ores; in construction, it sifts aggregates; and in the food industry, it sorts grains.

We offer custom-made meshes that can be tailored to specific mesh sizes, shapes, or additional features. This ensures that we can meet the diverse needs of our customers.

A wide range of mesh sizes is available, spanning from 0.1mm aperture for fine screening to 50mm for coarse separation. This allows for the precise sorting of various materials, whether it's fine powders in the chemical industry or large-sized aggregates in construction.

The mesh is primarily composed of high-grade manganese steel, with the manganese content typically ranging from 11% - 14%. This specific alloy composition endows it with excellent wear resistance and toughness, ensuring its long-term use in harsh working conditions.

It exhibits a high tensile strength of 800 - 1200 MPa. This strong tensile property enables the screen mesh to withstand heavy loads during operation, such as in continuous mining conveyor systems where large volumes of materials pass through.

The mesh can endure significant impact forces. In standardized impact tests, it can withstand impacts of up to 20 J without deforming, making it suitable for applications where sudden impacts are common, like in vibrating screening machines used in the mining industry.

It is rated as highly corrosion-resistant. After 1000-hour salt-spray tests, it shows no signs of rust or degradation, which is crucial for its use in humid or corrosive environments such as coastal construction sites or chemical processing plants.

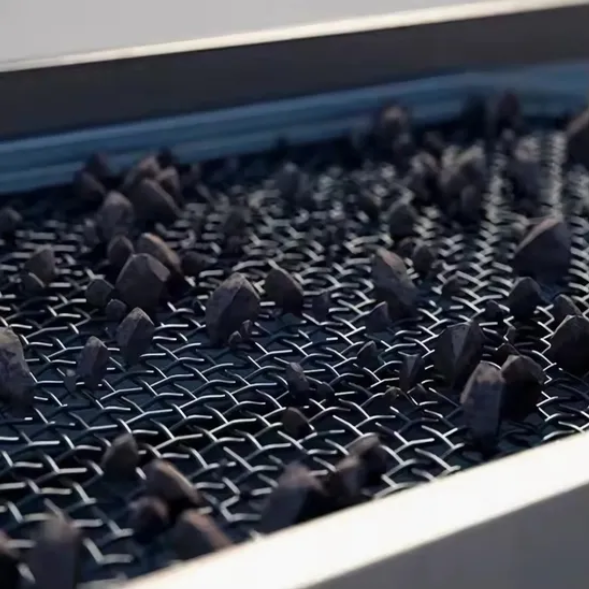

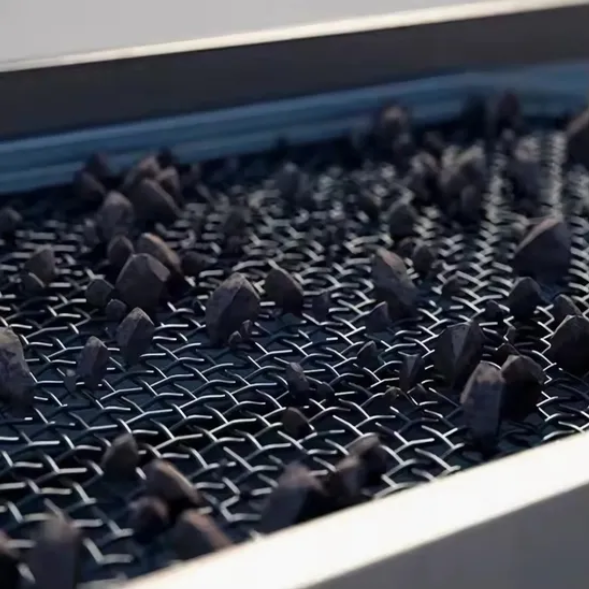

In the mining sector, manganese steel screen mesh is used to separate ores from gangue. Its sturdy construction provides resistance to ore abrasion. For example, in gold mines, it sizes ore particles to facilitate easier extraction.

In construction, this mesh is employed to sift aggregates like sand and gravel. It ensures that the particles are of the proper size for high-quality concrete mixing.

Food plants utilize this mesh to sift grains and flour. Fine-meshed versions are used to remove impurities, thereby safeguarding food safety.

In the chemical industry, the mesh is used to screen powders and granules. It classifies products by size, ensuring consistent quality, as seen in fertilizer production.

Recycling facilities depend on this mesh to separate metals, plastics, and glass by size, thereby enhancing recycling efficiency.

Q1: What makes manganese steel suitable for screen meshes?

A1: Manganese steel has high wear - resistance and toughness. Its alloy composition, with 11% - 14% manganese, enables it to endure harsh conditions, making it ideal for screen meshes in various industries.

Q2: How long does the manganese steel screen mesh typically last?

A2: It depends on usage. In mining, with heavy - duty use, it can last 6 - 12 months. In less - demanding applications like food processing, it may last 1 - 2 years due to its durability.

Q3: Can the mesh be cleaned easily?

A3: Yes. For most applications, a simple water rinse or gentle brushing can remove debris. In cases of stubborn dirt, mild detergents can be used without affecting the mesh's integrity.

Q4: Is it possible to customize the mesh size?

A4: Absolutely. We offer a wide range of custom - made mesh sizes, from very fine to coarse, to meet specific industry needs. Just let us know your requirements.

Manganese steel screen mesh is a robust and enduring product, crafted from premium-quality manganese steel. Its remarkable wear resistance makes it an ideal choice for harsh operating conditions.

This mesh is extensively utilized in mining, construction, and industrial screening operations to effectively separate materials based on size. Its sturdy construction enables it to bear heavy loads and withstand continuous vibration. With a variety of mesh sizes available, it can cater to different screening requirements, making it a reliable option for industries in search of durable and high-performance screening solutions.

Due to its unique alloy composition, manganese steel screen mesh exhibits outstanding durability. Tests have shown that it is 3 - 5 times more wear-resistant than ordinary steel meshes, making it particularly well-suited for mining and other industries that involve high levels of friction.

With precise mesh sizing, this screen mesh enables highly efficient screening. For instance, in sand screening processes, it can achieve a separation accuracy of up to 95%, thereby saving time and boosting productivity.

This mesh demonstrates excellent resistance to corrosion. After undergoing 1000-hour salt-spray tests, it remains free of rust, outperforming many other metal meshes and significantly extending its service life in various industrial environments.

It finds applications across a range of sectors, including mining, construction, and food processing. In the mining industry, it is used to separate ores; in construction, it sifts aggregates; and in the food industry, it sorts grains.

We offer custom-made meshes that can be tailored to specific mesh sizes, shapes, or additional features. This ensures that we can meet the diverse needs of our customers.

A wide range of mesh sizes is available, spanning from 0.1mm aperture for fine screening to 50mm for coarse separation. This allows for the precise sorting of various materials, whether it's fine powders in the chemical industry or large-sized aggregates in construction.

The mesh is primarily composed of high-grade manganese steel, with the manganese content typically ranging from 11% - 14%. This specific alloy composition endows it with excellent wear resistance and toughness, ensuring its long-term use in harsh working conditions.

It exhibits a high tensile strength of 800 - 1200 MPa. This strong tensile property enables the screen mesh to withstand heavy loads during operation, such as in continuous mining conveyor systems where large volumes of materials pass through.

The mesh can endure significant impact forces. In standardized impact tests, it can withstand impacts of up to 20 J without deforming, making it suitable for applications where sudden impacts are common, like in vibrating screening machines used in the mining industry.

It is rated as highly corrosion-resistant. After 1000-hour salt-spray tests, it shows no signs of rust or degradation, which is crucial for its use in humid or corrosive environments such as coastal construction sites or chemical processing plants.

In the mining sector, manganese steel screen mesh is used to separate ores from gangue. Its sturdy construction provides resistance to ore abrasion. For example, in gold mines, it sizes ore particles to facilitate easier extraction.

In construction, this mesh is employed to sift aggregates like sand and gravel. It ensures that the particles are of the proper size for high-quality concrete mixing.

Food plants utilize this mesh to sift grains and flour. Fine-meshed versions are used to remove impurities, thereby safeguarding food safety.

In the chemical industry, the mesh is used to screen powders and granules. It classifies products by size, ensuring consistent quality, as seen in fertilizer production.

Recycling facilities depend on this mesh to separate metals, plastics, and glass by size, thereby enhancing recycling efficiency.

Q1: What makes manganese steel suitable for screen meshes?

A1: Manganese steel has high wear - resistance and toughness. Its alloy composition, with 11% - 14% manganese, enables it to endure harsh conditions, making it ideal for screen meshes in various industries.

Q2: How long does the manganese steel screen mesh typically last?

A2: It depends on usage. In mining, with heavy - duty use, it can last 6 - 12 months. In less - demanding applications like food processing, it may last 1 - 2 years due to its durability.

Q3: Can the mesh be cleaned easily?

A3: Yes. For most applications, a simple water rinse or gentle brushing can remove debris. In cases of stubborn dirt, mild detergents can be used without affecting the mesh's integrity.

Q4: Is it possible to customize the mesh size?

A4: Absolutely. We offer a wide range of custom - made mesh sizes, from very fine to coarse, to meet specific industry needs. Just let us know your requirements.