- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

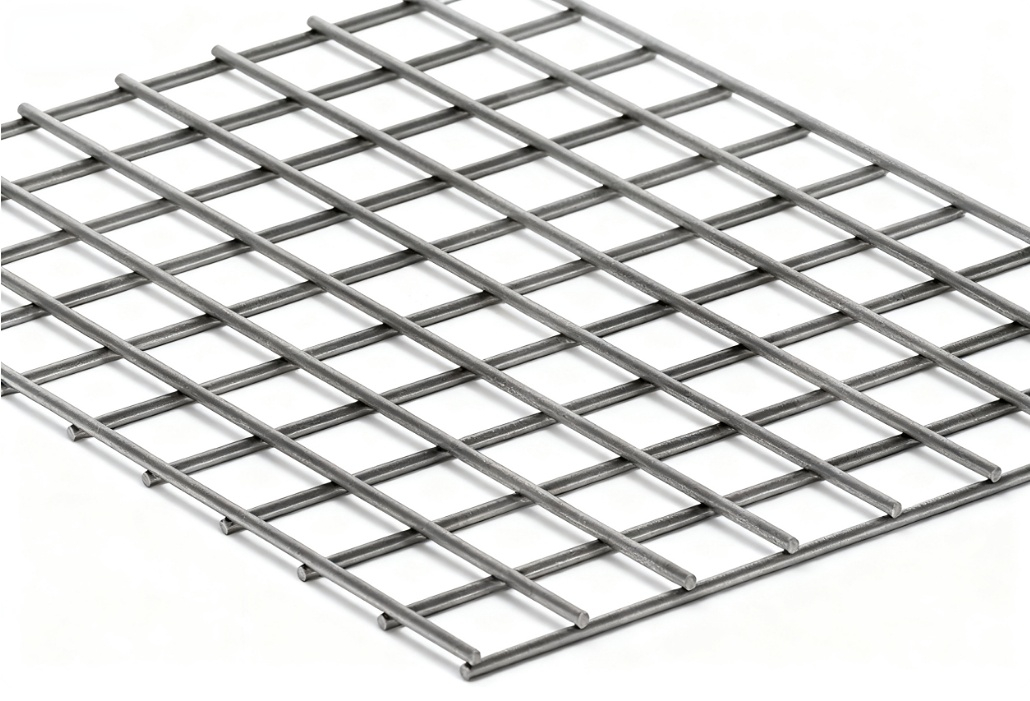

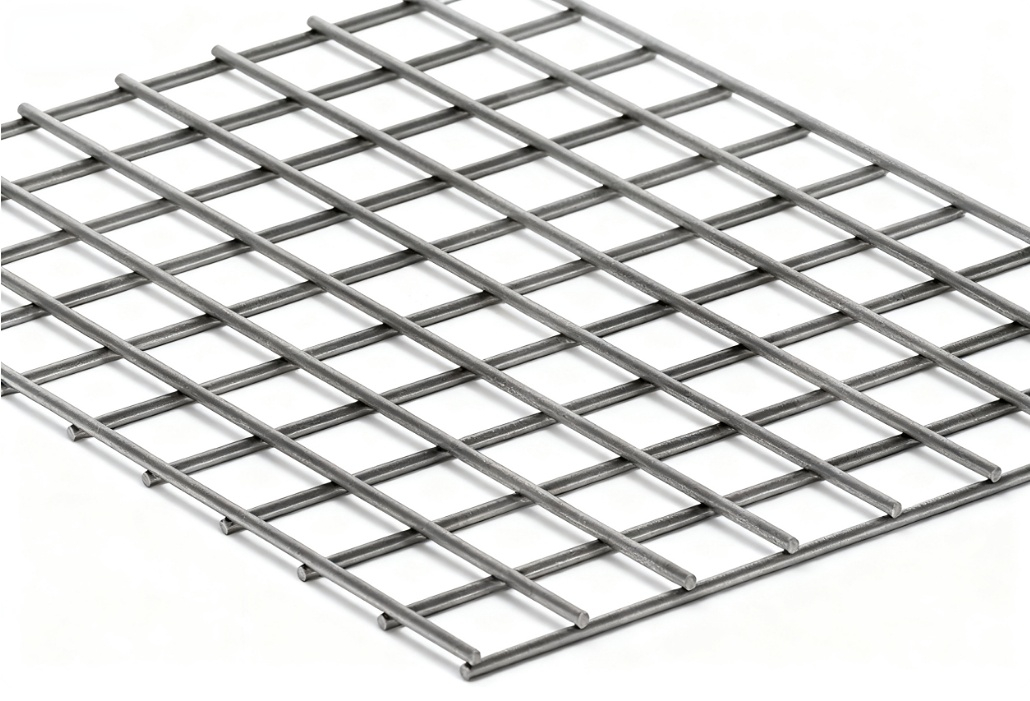

Welded steel wire mesh is a multifunctional mesh material formed by welding intersecting steel wires, with diverse specifications including wire diameter (0.5-6mm), mesh size (10mm × 10mm-200mm × 200mm), and size (width 0.5-3m, length 1-50m can be customized). It achieves high strength, corrosion resistance, and economy through galvanizing/PVC coating treatment, and is suitable for the needs of multiple industries.

Long term durability: High quality steel wire substrate+galvanized/PVC coating. The galvanized version has passed 500 hours of salt spray testing without significant corrosion. The PVC coating further strengthens the anti-corrosion and is suitable for long-term use in harsh outdoor environments;

Precision manufacturing process: Advanced welding technology achieves precise cross point forming, with uniform and firm welding points and a tensile strength of 80N/mm ², ensuring structural integrity and load-bearing performance;

Flexible specification adaptation: The wire diameter, mesh and size support customized selection, covering precise needs in scenarios such as building reinforcement, agricultural fences, industrial screening, etc;

Outstanding cost-effectiveness: Through production optimization and economies of scale, the price is reduced by 65% compared to similar products, balancing high performance and economy.

The material system is compatible with processes such as galvanizing and PVC coating; Welding strength is ensured through uniform welding points; Corrosion resistance has been verified through salt spray testing; The size specifications support multidimensional customization of width, length, and mesh size, ensuring the strength, durability, and adaptability requirements of the product in different mechanical scenarios.

In the field of architecture: concrete reinforcement (such as stress dispersion and enhancement of high-rise building slabs/walls to improve structural stability);

Agricultural scenario: fence protection (for captive livestock, to resist predators, suitable for long-term outdoor use on farms);

Industrial screening: precise separation of materials of different sizes (such as screening and filtration in mining and food processing);

Security protection: Security barriers (peripheral protection of factories/warehouses/residential areas, blocking intruders and enhancing security).

Through the above hierarchical sorting, the welded steel wire mesh is structured from defining characteristics to advantageous technologies, and then to specific application scenarios, forming a logical and complete expression of information, which facilitates a quick grasp of its core value and scope of application.

Q1: How durable is the welded wire mesh?

A: Our welded wire mesh is highly durable. Made from quality steel and with corrosion - resistant treatments like galvanizing, it can withstand harsh conditions for years, ensuring long - term use.

Q2: Can the mesh size be customized?

A: Yes, we offer customization. Whether you need a specific wire diameter or mesh size, we can meet your requirements to fit your unique application needs precisely.

Q3: Is it easy to install the welded wire mesh?

A: Installation is relatively easy. The mesh is lightweight yet sturdy. With basic tools, it can be quickly set up for fencing, reinforcement, or screening purposes.

Q4: How much does the welded wire mesh cost?

A: The price varies based on factors like material, size, and quantity. But we strive for cost - effectiveness. Contact us, and we'll provide a competitive quote based on your order details.

Welded steel wire mesh is a multifunctional mesh material formed by welding intersecting steel wires, with diverse specifications including wire diameter (0.5-6mm), mesh size (10mm × 10mm-200mm × 200mm), and size (width 0.5-3m, length 1-50m can be customized). It achieves high strength, corrosion resistance, and economy through galvanizing/PVC coating treatment, and is suitable for the needs of multiple industries.

Long term durability: High quality steel wire substrate+galvanized/PVC coating. The galvanized version has passed 500 hours of salt spray testing without significant corrosion. The PVC coating further strengthens the anti-corrosion and is suitable for long-term use in harsh outdoor environments;

Precision manufacturing process: Advanced welding technology achieves precise cross point forming, with uniform and firm welding points and a tensile strength of 80N/mm ², ensuring structural integrity and load-bearing performance;

Flexible specification adaptation: The wire diameter, mesh and size support customized selection, covering precise needs in scenarios such as building reinforcement, agricultural fences, industrial screening, etc;

Outstanding cost-effectiveness: Through production optimization and economies of scale, the price is reduced by 65% compared to similar products, balancing high performance and economy.

The material system is compatible with processes such as galvanizing and PVC coating; Welding strength is ensured through uniform welding points; Corrosion resistance has been verified through salt spray testing; The size specifications support multidimensional customization of width, length, and mesh size, ensuring the strength, durability, and adaptability requirements of the product in different mechanical scenarios.

In the field of architecture: concrete reinforcement (such as stress dispersion and enhancement of high-rise building slabs/walls to improve structural stability);

Agricultural scenario: fence protection (for captive livestock, to resist predators, suitable for long-term outdoor use on farms);

Industrial screening: precise separation of materials of different sizes (such as screening and filtration in mining and food processing);

Security protection: Security barriers (peripheral protection of factories/warehouses/residential areas, blocking intruders and enhancing security).

Through the above hierarchical sorting, the welded steel wire mesh is structured from defining characteristics to advantageous technologies, and then to specific application scenarios, forming a logical and complete expression of information, which facilitates a quick grasp of its core value and scope of application.

Q1: How durable is the welded wire mesh?

A: Our welded wire mesh is highly durable. Made from quality steel and with corrosion - resistant treatments like galvanizing, it can withstand harsh conditions for years, ensuring long - term use.

Q2: Can the mesh size be customized?

A: Yes, we offer customization. Whether you need a specific wire diameter or mesh size, we can meet your requirements to fit your unique application needs precisely.

Q3: Is it easy to install the welded wire mesh?

A: Installation is relatively easy. The mesh is lightweight yet sturdy. With basic tools, it can be quickly set up for fencing, reinforcement, or screening purposes.

Q4: How much does the welded wire mesh cost?

A: The price varies based on factors like material, size, and quantity. But we strive for cost - effectiveness. Contact us, and we'll provide a competitive quote based on your order details.