- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

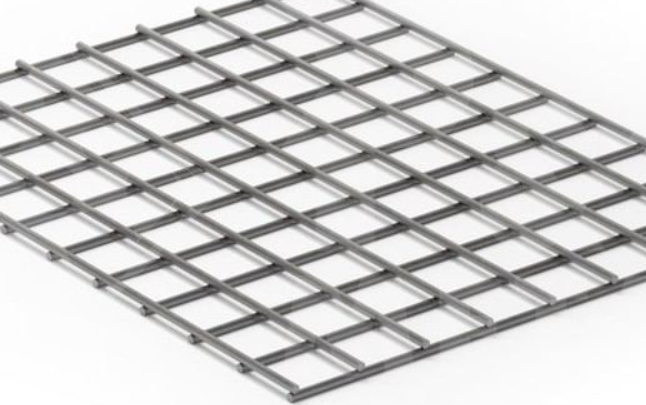

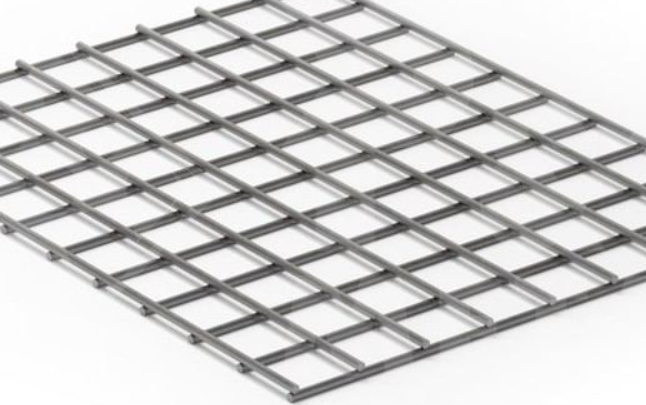

Welded steel wire mesh, as a multifunctional material, is formed by connecting cross steel wire welding points and has a variety of wire diameters and mesh specifications to choose from. This product is widely used in multiple industries due to its structural strength, durability, and cost advantages. In the field of architecture, it is commonly used for concrete reinforcement to enhance structural stability by dispersing stress, such as the reinforcement of concrete floors and walls in high-rise buildings; In agricultural scenarios, it serves as a durable fence that can both house livestock and resist external threats. Its anti-corrosion properties are suitable for long-term outdoor exposure environments; In the industrial field, its precise mesh is used to achieve efficient screening and filtration, such as mineral sorting or material grading in food processing.

Long term protective performance - using high-quality steel wire substrate, supplemented by galvanized or PVC coating process, forming a dual anti-corrosion barrier. Through experimental verification, the galvanized version can withstand salt spray erosion for more than 500 hours without significant corrosion, and the PVC coating further enhances environmental adaptability, ensuring long-term use under harsh working conditions.

Precision manufacturing process - relying on advanced welding technology to achieve precise cross point forming, with uniform weld strength and tensile strength up to 80N/mm ², ensuring the integrity and load-bearing performance of the grid structure, and meeting high-precision engineering requirements.

Flexible customization of specifications - providing a wire diameter range from 0.5mm to 6mm, with mesh sizes covering 10mm × 10mm to 200mm × 200mm, widths supporting 0.5m to 3m, and lengths customizable from 1m to 50m, fully adapting to the size requirements of different scenarios such as building reinforcement, agricultural protection, and industrial screening.

Outstanding cost-effectiveness - Despite using high-quality raw materials and precision craftsmanship, the product still maintains market competitiveness. By optimizing the production process and scaling up manufacturing, the price has been reduced by 65% compared to similar solutions, achieving a dual advantage of high performance and economy.

In terms of technical parameters, the material system is compatible with processes such as galvanizing and PVC coating; Welding strength is ensured through uniform welding points; Corrosion resistance has been verified through salt spray testing; The size specifications support multidimensional customization of width, length, and mesh size. These parameters collectively ensure that the product can provide reliable performance support in scenarios such as mechanical engineering, building reinforcement, protective barriers, and material screening. Its specific application scenarios include: building concrete reinforcement, agricultural fence protection, industrial fine screening, and safety protection barriers, etc. It meets the engineering requirements of various scenarios through structural strength and material properties.

A: Our welded wire mesh is highly durable. Made from quality steel and with corrosion - resistant treatments like galvanizing, it can withstand harsh conditions for years, ensuring long - term use.

A: Yes, we offer customization. Whether you need a specific wire diameter or mesh size, we can meet your requirements to fit your unique application needs precisely.

A: Installation is relatively easy. The mesh is lightweight yet sturdy. With basic tools, it can be quickly set up for fencing, reinforcement, or screening purposes.

A: The price varies based on factors like material, size, and quantity. But we strive for cost - effectiveness. Contact us, and we'll provide a competitive quote based on your order details.

Welded steel wire mesh, as a multifunctional material, is formed by connecting cross steel wire welding points and has a variety of wire diameters and mesh specifications to choose from. This product is widely used in multiple industries due to its structural strength, durability, and cost advantages. In the field of architecture, it is commonly used for concrete reinforcement to enhance structural stability by dispersing stress, such as the reinforcement of concrete floors and walls in high-rise buildings; In agricultural scenarios, it serves as a durable fence that can both house livestock and resist external threats. Its anti-corrosion properties are suitable for long-term outdoor exposure environments; In the industrial field, its precise mesh is used to achieve efficient screening and filtration, such as mineral sorting or material grading in food processing.

Long term protective performance - using high-quality steel wire substrate, supplemented by galvanized or PVC coating process, forming a dual anti-corrosion barrier. Through experimental verification, the galvanized version can withstand salt spray erosion for more than 500 hours without significant corrosion, and the PVC coating further enhances environmental adaptability, ensuring long-term use under harsh working conditions.

Precision manufacturing process - relying on advanced welding technology to achieve precise cross point forming, with uniform weld strength and tensile strength up to 80N/mm ², ensuring the integrity and load-bearing performance of the grid structure, and meeting high-precision engineering requirements.

Flexible customization of specifications - providing a wire diameter range from 0.5mm to 6mm, with mesh sizes covering 10mm × 10mm to 200mm × 200mm, widths supporting 0.5m to 3m, and lengths customizable from 1m to 50m, fully adapting to the size requirements of different scenarios such as building reinforcement, agricultural protection, and industrial screening.

Outstanding cost-effectiveness - Despite using high-quality raw materials and precision craftsmanship, the product still maintains market competitiveness. By optimizing the production process and scaling up manufacturing, the price has been reduced by 65% compared to similar solutions, achieving a dual advantage of high performance and economy.

In terms of technical parameters, the material system is compatible with processes such as galvanizing and PVC coating; Welding strength is ensured through uniform welding points; Corrosion resistance has been verified through salt spray testing; The size specifications support multidimensional customization of width, length, and mesh size. These parameters collectively ensure that the product can provide reliable performance support in scenarios such as mechanical engineering, building reinforcement, protective barriers, and material screening. Its specific application scenarios include: building concrete reinforcement, agricultural fence protection, industrial fine screening, and safety protection barriers, etc. It meets the engineering requirements of various scenarios through structural strength and material properties.

A: Our welded wire mesh is highly durable. Made from quality steel and with corrosion - resistant treatments like galvanizing, it can withstand harsh conditions for years, ensuring long - term use.

A: Yes, we offer customization. Whether you need a specific wire diameter or mesh size, we can meet your requirements to fit your unique application needs precisely.

A: Installation is relatively easy. The mesh is lightweight yet sturdy. With basic tools, it can be quickly set up for fencing, reinforcement, or screening purposes.

A: The price varies based on factors like material, size, and quantity. But we strive for cost - effectiveness. Contact us, and we'll provide a competitive quote based on your order details.