- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

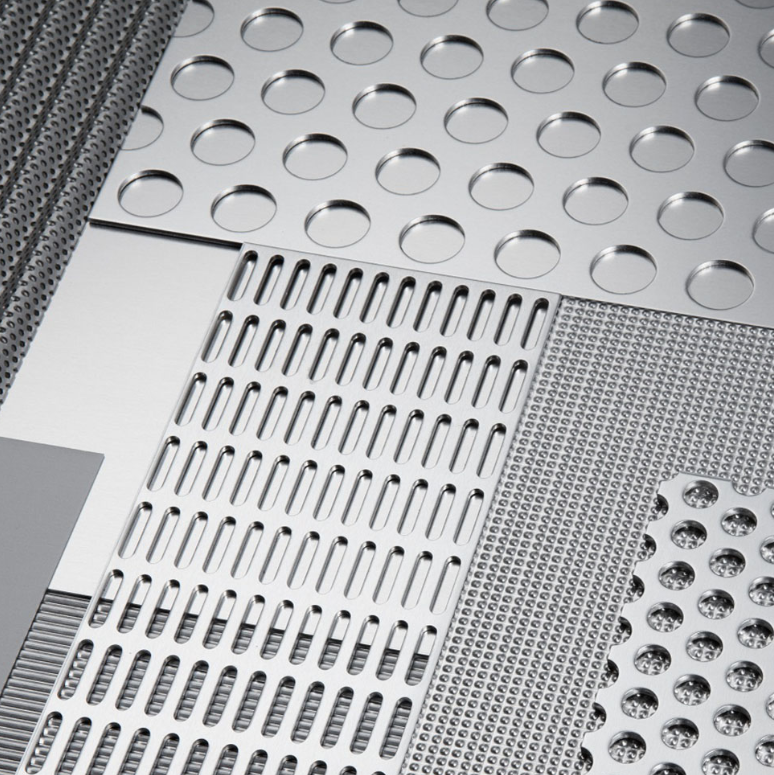

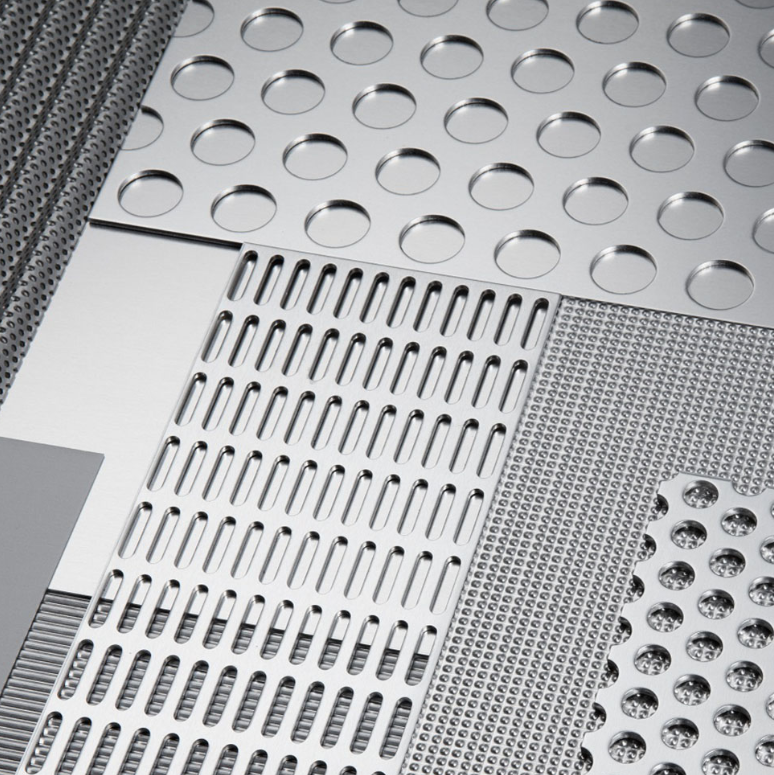

Perforated metal mesh is crafted using precision stamping technology, and with its diverse hole patterns (round/square/hexagonal) and flexible dimensions (0.1-50mm), it has become a model for cross disciplinary multifunctional materials. Its core advantages are reflected in five dimensions:

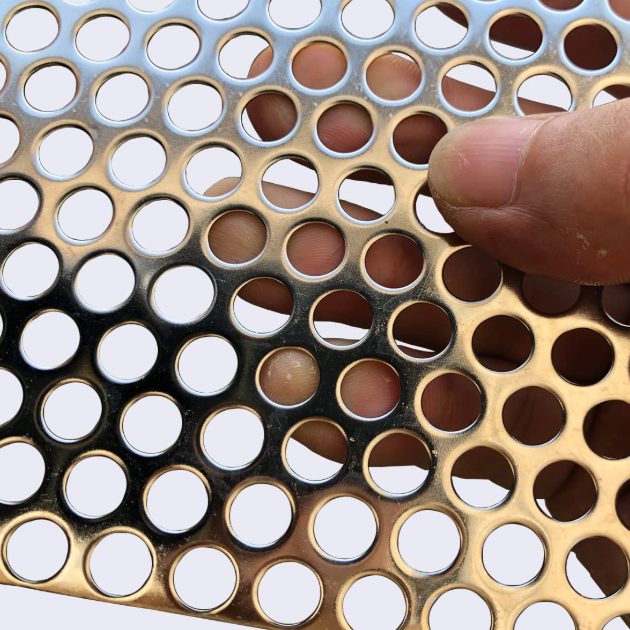

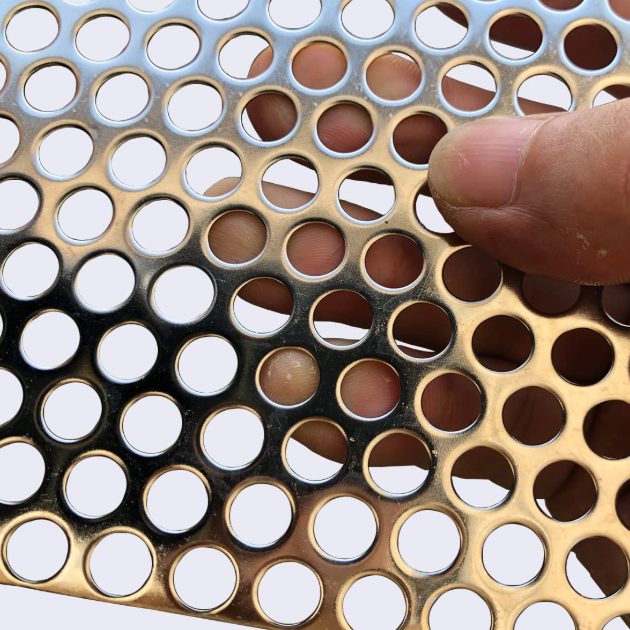

Precision manufacturing: Using ± 0.05mm aperture control technology, it achieves precise adaptation from 5-micron ultra-fine filtration to 50mm large aperture ventilation in all scenarios, meeting high requirements such as semiconductor clean production and precision instrument protection.

Excellent material: 304/316 stainless steel base material has been verified by over 1000 hours of salt spray test, and it is stable in coastal chemical industry, ship platform and other corrosive environments for a long time. Its service life is 2-3 times longer than that of ordinary steel.

Structural optimization: Achieving a balance between high tensile strength of 500MPa and low density of 1.8kg/m ³ through scientific arrangement of holes, achieving a weight reduction of 40% while maintaining structural stiffness in spacecraft thermal control and automotive lightweight components.

Functional combination: 80% high airflow rate combined with 5-micron filtration capacity, ensuring air circulation and blocking particulate matter, widely used in data center cooling systems and airport terminal curtain wall ventilation projects.

Aesthetic customization: Supports irregular hole design and non-standard size cutting, creating dynamic visual effects through light and shadow changes in building facades and interior decoration, enhancing the aesthetic value of architecture.

This material is widely used in fields such as petroleum refining filtration, building energy-saving ventilation, spacecraft component manufacturing, security fence systems, etc. It has passed ISO certification and CE safety standards, and is a landmark product of functional material innovation in the Industry 4.0 era.

FAQ:

Q1: Can the hole size be customized?

A1: Absolutely! Our 1 - perforated metal mesh offers hole sizes ranging from 0.1mm to 50mm. We can tailor it to your specific needs, ensuring it fits your application perfectly.

Q2: How well does it resist corrosion?

A2: Made of 304 or 316 stainless steel, it passes over 1000 - hour salt - spray tests. It's highly resistant to corrosion, suitable for harsh environments like coastal areas.

Q3: Is it suitable for high - temperature applications?

A3: Yes, the 304/316 stainless - steel mesh can withstand high temperatures. It maintains its structural integrity, making it applicable in industrial settings with heat exposure.

Q4: Can it be used for fine - particle filtration?

A4: Certainly. Its precise hole sizes can filter particles as small as 5 microns, ideal for high - end liquid and gas filtration in refineries and water treatment.

Perforated metal mesh is crafted using precision stamping technology, and with its diverse hole patterns (round/square/hexagonal) and flexible dimensions (0.1-50mm), it has become a model for cross disciplinary multifunctional materials. Its core advantages are reflected in five dimensions:

Precision manufacturing: Using ± 0.05mm aperture control technology, it achieves precise adaptation from 5-micron ultra-fine filtration to 50mm large aperture ventilation in all scenarios, meeting high requirements such as semiconductor clean production and precision instrument protection.

Excellent material: 304/316 stainless steel base material has been verified by over 1000 hours of salt spray test, and it is stable in coastal chemical industry, ship platform and other corrosive environments for a long time. Its service life is 2-3 times longer than that of ordinary steel.

Structural optimization: Achieving a balance between high tensile strength of 500MPa and low density of 1.8kg/m ³ through scientific arrangement of holes, achieving a weight reduction of 40% while maintaining structural stiffness in spacecraft thermal control and automotive lightweight components.

Functional combination: 80% high airflow rate combined with 5-micron filtration capacity, ensuring air circulation and blocking particulate matter, widely used in data center cooling systems and airport terminal curtain wall ventilation projects.

Aesthetic customization: Supports irregular hole design and non-standard size cutting, creating dynamic visual effects through light and shadow changes in building facades and interior decoration, enhancing the aesthetic value of architecture.

This material is widely used in fields such as petroleum refining filtration, building energy-saving ventilation, spacecraft component manufacturing, security fence systems, etc. It has passed ISO certification and CE safety standards, and is a landmark product of functional material innovation in the Industry 4.0 era.

FAQ:

Q1: Can the hole size be customized?

A1: Absolutely! Our 1 - perforated metal mesh offers hole sizes ranging from 0.1mm to 50mm. We can tailor it to your specific needs, ensuring it fits your application perfectly.

Q2: How well does it resist corrosion?

A2: Made of 304 or 316 stainless steel, it passes over 1000 - hour salt - spray tests. It's highly resistant to corrosion, suitable for harsh environments like coastal areas.

Q3: Is it suitable for high - temperature applications?

A3: Yes, the 304/316 stainless - steel mesh can withstand high temperatures. It maintains its structural integrity, making it applicable in industrial settings with heat exposure.

Q4: Can it be used for fine - particle filtration?

A4: Certainly. Its precise hole sizes can filter particles as small as 5 microns, ideal for high - end liquid and gas filtration in refineries and water treatment.