- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

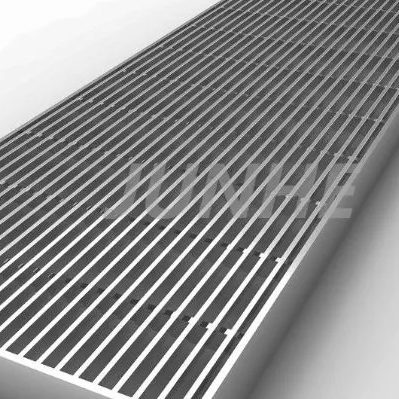

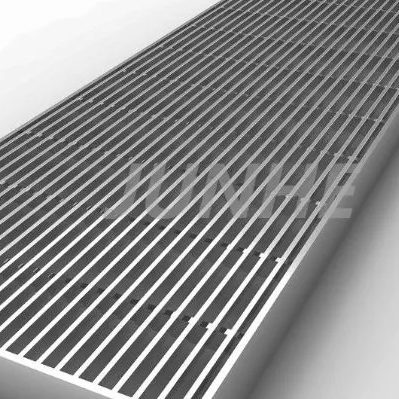

The drainage grille (also known as the drainage cover) is the core component of the drainage system, and common materials include metal (such as stainless steel, cast iron, brass), plastic, and composite materials. Its main function is to intercept large debris such as fallen leaves, branches, and garbage, prevent blockages in drainage pipes, and ensure smooth drainage. It is commonly used in streets, parking lots, building entrances, shower areas, and other scenarios. It also provides various shapes such as square, circular, and rectangular to meet different usage needs.

Core strengths

High strength and durability: Made of high-quality stainless steel, high-strength cast iron and other materials, the stainless steel version can bear up to 8000 kilograms, suitable for high load scenarios such as industrial parks and commercial lanes, reducing replacement frequency and saving expenses.

High drainage efficiency: adopting a dedicated perforated structure, the drainage capacity reaches 10000 liters/minute, and the hole type is optimized to avoid blockage by debris, suitable for rainy or water prone areas.

Safety and anti slip: The surface has been treated with anti slip measures. In rainy weather or when exposed to industrial liquids, the friction coefficient should be at least 0.75, which can reduce the risk of pedestrians and vehicles slipping.

Support customization: Customizable shapes (square, circular, rectangular), sizes, and hole patterns, such as the special groove grille that has been customized for modern architectural complexes before.

Excellent corrosion resistance: Stainless steel material or grille with anti-corrosion coating can resist corrosive media such as salt and acid, with almost no loss after more than 20 years of use, suitable for coastal or chemical areas.

key parameters

1. Material selection

Load bearing flat steel: Q235A carbon steel (cost-effective) or 304/316 stainless steel (better corrosion resistance) can be selected.

Horizontal bar: Q235A or 304 stainless steel can be selected, with shapes including circular, twisted square steel (5 × 5mm-8 × 8mm), square, and hexagonal, which can enhance stability.

2. Size specifications

Flat steel: thickness range 3-10mm (such as 25 × 3mm to 100 × 10mm), width set according to load-bearing requirements.

Grille: The center spacing of the flat steel is 30/40/60mm, and the spacing of the horizontal bars is 100/50mm.

Overall: There are standard sizes available (standard width 995mm, including 5mm installation gap), and customization is also supported.

3. Load bearing grade

Light load: 25 tons/square meter, suitable for residential walkways, parks, and light vehicle parking areas.

Medium load: 70 tons/square meter, suitable for factory areas and ordinary roads for vehicles under 20 tons.

Heavy load: 140 tons/square meter, suitable for high load areas such as main roads and industrial docks.

4. Surface treatment

Hot dip galvanizing: The thickness of the zinc layer is 85 μ m, and the normal service life exceeds 20 years.

Cold galvanizing: The coating is relatively thin, suitable for scenarios with lower requirements.

Spray paint: There are various colors of anti rust paint, which are both beautiful and corrosion-resistant.

5. Drainage and anti slip performance

Drainage efficiency: The maximum leakage area is 83.3%, and under rainfall conditions of 50mm/h, it can drain 1000 liters per square meter per minute.

Slip resistance: In wet or oily environments, the friction coefficient should not be less than 0.6.

Main application scenarios

Urban streets: installed at the roadside drainage ditch, capable of bearing the weight of vehicles, quickly draining rainwater, preventing water accumulation, and ensuring traffic and pedestrian safety.

Industrial park: The grilles in workshops and loading and unloading areas can withstand chemical leaks and have good durability, which can withstand heavy equipment driving.

Commercial buildings: shopping malls, office entrances, parking lots, and basements use it for drainage, and anti slip surfaces can improve safety.

Residential areas: Use it to solve drainage problems for lanes and sidewalks, and can meet aesthetic needs through customized design.

Leisure facilities: Park fountains, amusement park trails, and sports venue changing rooms are quickly drained to maintain a clean and safe environment.

Q: What's the lifespan of the steel grilles?

A: Our steel grilles, especially when hot - dip galvanized, can last over 20 years in normal conditions. Their robust material ensures long - term durability against wear and corrosion.

Q: Are they easy to install?

A: Yes. Standard - sized grilles come with a 5 - mm installation gap for easy fitting. They can be quickly placed in position. Custom - sized ones also have straightforward installation procedures.

Q: How to clean the grilles?

A: Regularly remove debris with a broom or shovel. For stubborn dirt or stains, use a mild detergent and water. In industrial settings, power - washing may be needed to handle heavy - duty grime.

Q: Can the grilles bear heavy loads?

A: Absolutely. They're designed with different load - bearing capacities. Heavy - duty grilles can withstand up to 140 tons/m², suitable for areas with heavy - truck traffic.

Q: Do you offer customization?

A: Yes, we provide customization in terms of size, shape, and hole patterns. This allows the grilles to meet specific project requirements, whether for aesthetics or functionality.

The drainage grille (also known as the drainage cover) is the core component of the drainage system, and common materials include metal (such as stainless steel, cast iron, brass), plastic, and composite materials. Its main function is to intercept large debris such as fallen leaves, branches, and garbage, prevent blockages in drainage pipes, and ensure smooth drainage. It is commonly used in streets, parking lots, building entrances, shower areas, and other scenarios. It also provides various shapes such as square, circular, and rectangular to meet different usage needs.

Core strengths

High strength and durability: Made of high-quality stainless steel, high-strength cast iron and other materials, the stainless steel version can bear up to 8000 kilograms, suitable for high load scenarios such as industrial parks and commercial lanes, reducing replacement frequency and saving expenses.

High drainage efficiency: adopting a dedicated perforated structure, the drainage capacity reaches 10000 liters/minute, and the hole type is optimized to avoid blockage by debris, suitable for rainy or water prone areas.

Safety and anti slip: The surface has been treated with anti slip measures. In rainy weather or when exposed to industrial liquids, the friction coefficient should be at least 0.75, which can reduce the risk of pedestrians and vehicles slipping.

Support customization: Customizable shapes (square, circular, rectangular), sizes, and hole patterns, such as the special groove grille that has been customized for modern architectural complexes before.

Excellent corrosion resistance: Stainless steel material or grille with anti-corrosion coating can resist corrosive media such as salt and acid, with almost no loss after more than 20 years of use, suitable for coastal or chemical areas.

key parameters

1. Material selection

Load bearing flat steel: Q235A carbon steel (cost-effective) or 304/316 stainless steel (better corrosion resistance) can be selected.

Horizontal bar: Q235A or 304 stainless steel can be selected, with shapes including circular, twisted square steel (5 × 5mm-8 × 8mm), square, and hexagonal, which can enhance stability.

2. Size specifications

Flat steel: thickness range 3-10mm (such as 25 × 3mm to 100 × 10mm), width set according to load-bearing requirements.

Grille: The center spacing of the flat steel is 30/40/60mm, and the spacing of the horizontal bars is 100/50mm.

Overall: There are standard sizes available (standard width 995mm, including 5mm installation gap), and customization is also supported.

3. Load bearing grade

Light load: 25 tons/square meter, suitable for residential walkways, parks, and light vehicle parking areas.

Medium load: 70 tons/square meter, suitable for factory areas and ordinary roads for vehicles under 20 tons.

Heavy load: 140 tons/square meter, suitable for high load areas such as main roads and industrial docks.

4. Surface treatment

Hot dip galvanizing: The thickness of the zinc layer is 85 μ m, and the normal service life exceeds 20 years.

Cold galvanizing: The coating is relatively thin, suitable for scenarios with lower requirements.

Spray paint: There are various colors of anti rust paint, which are both beautiful and corrosion-resistant.

5. Drainage and anti slip performance

Drainage efficiency: The maximum leakage area is 83.3%, and under rainfall conditions of 50mm/h, it can drain 1000 liters per square meter per minute.

Slip resistance: In wet or oily environments, the friction coefficient should not be less than 0.6.

Main application scenarios

Urban streets: installed at the roadside drainage ditch, capable of bearing the weight of vehicles, quickly draining rainwater, preventing water accumulation, and ensuring traffic and pedestrian safety.

Industrial park: The grilles in workshops and loading and unloading areas can withstand chemical leaks and have good durability, which can withstand heavy equipment driving.

Commercial buildings: shopping malls, office entrances, parking lots, and basements use it for drainage, and anti slip surfaces can improve safety.

Residential areas: Use it to solve drainage problems for lanes and sidewalks, and can meet aesthetic needs through customized design.

Leisure facilities: Park fountains, amusement park trails, and sports venue changing rooms are quickly drained to maintain a clean and safe environment.

Q: What's the lifespan of the steel grilles?

A: Our steel grilles, especially when hot - dip galvanized, can last over 20 years in normal conditions. Their robust material ensures long - term durability against wear and corrosion.

Q: Are they easy to install?

A: Yes. Standard - sized grilles come with a 5 - mm installation gap for easy fitting. They can be quickly placed in position. Custom - sized ones also have straightforward installation procedures.

Q: How to clean the grilles?

A: Regularly remove debris with a broom or shovel. For stubborn dirt or stains, use a mild detergent and water. In industrial settings, power - washing may be needed to handle heavy - duty grime.

Q: Can the grilles bear heavy loads?

A: Absolutely. They're designed with different load - bearing capacities. Heavy - duty grilles can withstand up to 140 tons/m², suitable for areas with heavy - truck traffic.

Q: Do you offer customization?

A: Yes, we provide customization in terms of size, shape, and hole patterns. This allows the grilles to meet specific project requirements, whether for aesthetics or functionality.