- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

Analysis of Core Advantages

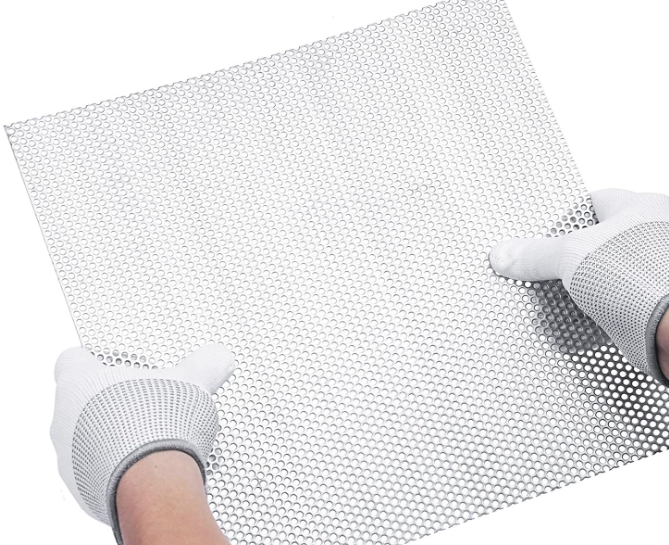

Perforated metal mesh uses precision stamping technology as its core to achieve precise control of hole shape and size. Its aperture tolerance is strictly controlled within ± 0.05 millimeters, supporting multiple hole types such as circular, square, hexagonal, etc. The aperture range covers 0.1 millimeters to 50 millimeters, meeting the full scenario requirements from 5-micron ultra-fine filtration to 50 millimeter large aperture ventilation. The material is made of top grade 304/316 stainless steel, which has been verified through over 1000 hours of salt spray testing. It is stable for a long time in harsh environments such as coastal chemical engineering, and its service life is 2-3 times longer than ordinary steel.

In terms of structure, the unique arrangement of holes achieves a balance between high tensile strength of 500MPa and lightweight design, reducing weight by 40% compared to solid steel plates. It is suitable for lightweight components in the aerospace and automotive fields. Functionally, with an 80% high airflow rate and a 5-micron particle filtration capacity, it not only ensures air circulation but also blocks impurities. It is widely used in data center cooling systems, hospital sterile room ventilation, and other scenarios.

Detailed description of parameter characteristics

The aperture accuracy reaches ± 0.05 millimeters, ensuring precise pattern shaping; The material is 304/316 stainless steel, and its corrosion resistance has passed the 1000 hour salt spray test; The hole type includes circular, square, and hexagonal shapes, and the size can be customized; The board size is cut according to the requirements, with a maximum tensile strength of 500MPa and a ventilation rate of 80%. It can filter particles as low as 5 microns.

Application scenario expansion

In industrial filtration systems, a precision pore size of 5 microns effectively removes impurities from refineries and water treatment plants; In the field of building ventilation and air conditioning, an 80% ventilation rate improves indoor air quality while blocking external debris; In terms of architectural decoration, the combination of customized hole patterns and stainless steel materials enhances the aesthetic value and weather resistance of building facades; In the fields of automobiles and aerospace, the high-strength and lightweight characteristics support the filtration and ventilation needs of engine components; In security fence scenarios, the sturdy structure and corrosion resistance provide long-term safety protection, suitable for industrial sites and residential protective facilities.

This material has passed multiple international certifications and meets the high requirements for functional materials in the Industry 4.0 era. It continues to expand its application boundaries in emerging fields such as new energy and ocean engineering, becoming a model of cross disciplinary multifunctional materials.

FAQ:

Q1: Can the hole size be customized?

A1: Absolutely! Our 1 - perforated metal mesh offers hole sizes ranging from 0.1mm to 50mm. We can tailor it to your specific needs, ensuring it fits your application perfectly.

Q2: How well does it resist corrosion?

A2: Made of 304 or 316 stainless steel, it passes over 1000 - hour salt - spray tests. It's highly resistant to corrosion, suitable for harsh environments like coastal areas.

Q3: Is it suitable for high - temperature applications?

A3: Yes, the 304/316 stainless - steel mesh can withstand high temperatures. It maintains its structural integrity, making it applicable in industrial settings with heat exposure.

Q4: Can it be used for fine - particle filtration?

A4: Certainly. Its precise hole sizes can filter particles as small as 5 microns, ideal for high - end liquid and gas filtration in refineries and water treatment.

Analysis of Core Advantages

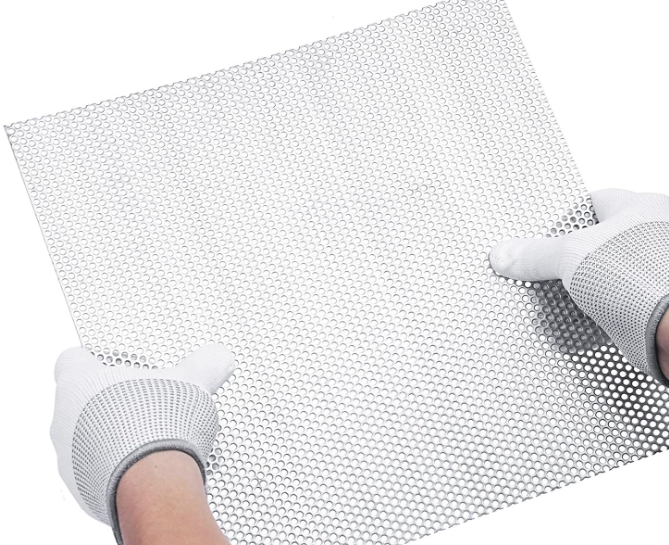

Perforated metal mesh uses precision stamping technology as its core to achieve precise control of hole shape and size. Its aperture tolerance is strictly controlled within ± 0.05 millimeters, supporting multiple hole types such as circular, square, hexagonal, etc. The aperture range covers 0.1 millimeters to 50 millimeters, meeting the full scenario requirements from 5-micron ultra-fine filtration to 50 millimeter large aperture ventilation. The material is made of top grade 304/316 stainless steel, which has been verified through over 1000 hours of salt spray testing. It is stable for a long time in harsh environments such as coastal chemical engineering, and its service life is 2-3 times longer than ordinary steel.

In terms of structure, the unique arrangement of holes achieves a balance between high tensile strength of 500MPa and lightweight design, reducing weight by 40% compared to solid steel plates. It is suitable for lightweight components in the aerospace and automotive fields. Functionally, with an 80% high airflow rate and a 5-micron particle filtration capacity, it not only ensures air circulation but also blocks impurities. It is widely used in data center cooling systems, hospital sterile room ventilation, and other scenarios.

Detailed description of parameter characteristics

The aperture accuracy reaches ± 0.05 millimeters, ensuring precise pattern shaping; The material is 304/316 stainless steel, and its corrosion resistance has passed the 1000 hour salt spray test; The hole type includes circular, square, and hexagonal shapes, and the size can be customized; The board size is cut according to the requirements, with a maximum tensile strength of 500MPa and a ventilation rate of 80%. It can filter particles as low as 5 microns.

Application scenario expansion

In industrial filtration systems, a precision pore size of 5 microns effectively removes impurities from refineries and water treatment plants; In the field of building ventilation and air conditioning, an 80% ventilation rate improves indoor air quality while blocking external debris; In terms of architectural decoration, the combination of customized hole patterns and stainless steel materials enhances the aesthetic value and weather resistance of building facades; In the fields of automobiles and aerospace, the high-strength and lightweight characteristics support the filtration and ventilation needs of engine components; In security fence scenarios, the sturdy structure and corrosion resistance provide long-term safety protection, suitable for industrial sites and residential protective facilities.

This material has passed multiple international certifications and meets the high requirements for functional materials in the Industry 4.0 era. It continues to expand its application boundaries in emerging fields such as new energy and ocean engineering, becoming a model of cross disciplinary multifunctional materials.

FAQ:

Q1: Can the hole size be customized?

A1: Absolutely! Our 1 - perforated metal mesh offers hole sizes ranging from 0.1mm to 50mm. We can tailor it to your specific needs, ensuring it fits your application perfectly.

Q2: How well does it resist corrosion?

A2: Made of 304 or 316 stainless steel, it passes over 1000 - hour salt - spray tests. It's highly resistant to corrosion, suitable for harsh environments like coastal areas.

Q3: Is it suitable for high - temperature applications?

A3: Yes, the 304/316 stainless - steel mesh can withstand high temperatures. It maintains its structural integrity, making it applicable in industrial settings with heat exposure.

Q4: Can it be used for fine - particle filtration?

A4: Certainly. Its precise hole sizes can filter particles as small as 5 microns, ideal for high - end liquid and gas filtration in refineries and water treatment.