- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 2025-09-26 Origin: Site

Punching Net: A Practical Solution for Industrial and Architectural Fields

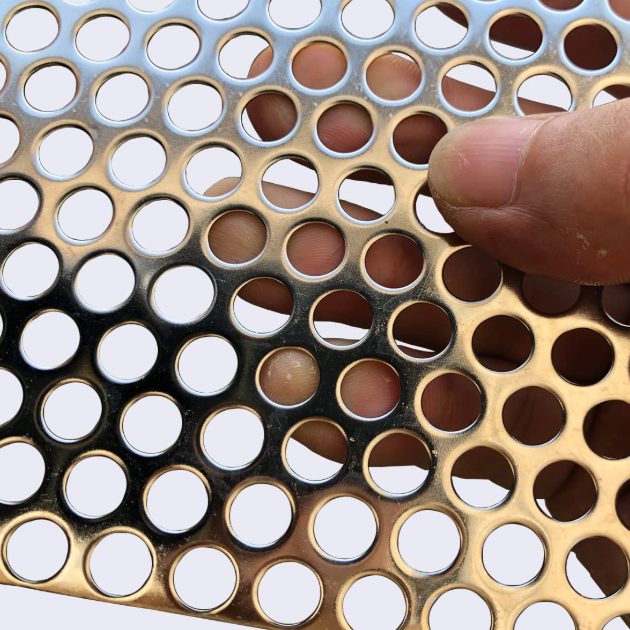

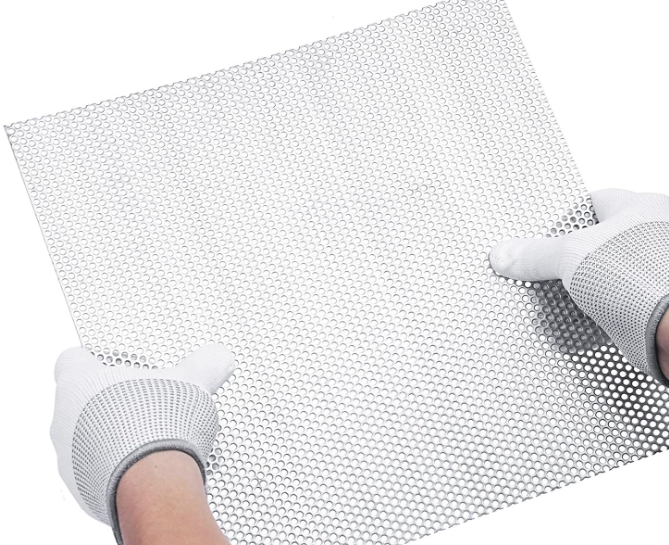

Punching mesh is made of metal plate as the substrate and formed through precision CNC stamping technology. The hole patterns cover various shapes such as round, square, and hexagonal, and the hole diameter range is adjustable from 0.1-50mm, forming a cross scenario applicability of "one material, multiple energy". Its core values are reflected in three practical dimensions:

1、 Hardcore support for technical parameters

Made of 304/316 duplex stainless steel material, verified by 1000 hours of salt spray testing, it maintains over 95% of its original strength in chemical acid alkali and oceanic climates, and has a service life three times longer than ordinary carbon steel. The aperture accuracy control reaches ± 0.05mm, achieving full scene coverage from 5-micron ultra-fine filtration (such as semiconductor cleanrooms) to 50mm large hole ventilation (such as factory heat dissipation). The structural optimization of 500MPa tensile strength and 1.8kg/m ³ low density enables it to achieve a weight reduction of 40% while maintaining structural stiffness in spacecraft thermal control systems and automotive lightweight components.

2、 Practical verification of scenario based applications

Industrial filtration: In petroleum catalytic cracking units, a 0.5mm diamond shaped mesh achieves a 99.97% retention rate of catalyst particles and a pressure drop loss of only 1.8kPa; In water treatment plants, 5-micron pore networks can intercept 99.2% of suspended solids, ensuring the quality of the effluent.

Building ventilation: The double skin curtain wall of Shanghai center Building adopts a punching net with an open area ratio of 80%. Combined with the principle of hot pressure ventilation, the annual energy saving efficiency is increased by 18%. At the same time, the dynamic facade effect is created through changes in the light and shadow of the holes.

Security protection: The prison perimeter protection system adopts 8mm thick hot-dip galvanized punched mesh, with a penetration resistance level of B3, and also has a 15 ° perspective monitoring function, achieving a balance between safety and visibility.

3、 Accurate response to customized services

Support full process customization from hole design (such as irregular trapezoid, diamond shape), aperture gradient (0.1-50mm continuously adjustable), sheet specifications (maximum roll width 2000mm) to surface treatment (spraying, anodizing). For example, Tesla's Shanghai Gigafactory uses a 0.8mm aperture triangular mesh, which meets both workshop ventilation requirements and industrial aesthetic standards; The ventilation system of the hospital sterile room adopts a 5-micron filter mesh, with an 80% ventilation rate, to maintain the ISO 14644 cleanroom standard.

This material has passed ISO 9001 quality system certification and EU CE safety certification, and continues to expand in emerging fields such as new energy storage and heat dissipation, ocean platform breakwaters, etc. With the three-dimensional advantages of "precise parameters+scene adaptation+customized services", it has become a practical choice for functional material innovation in the Industry 4.0 era.